Page 535 - ISCAR(MILLINGCATALOG 38_2021)

P. 535

Rd°

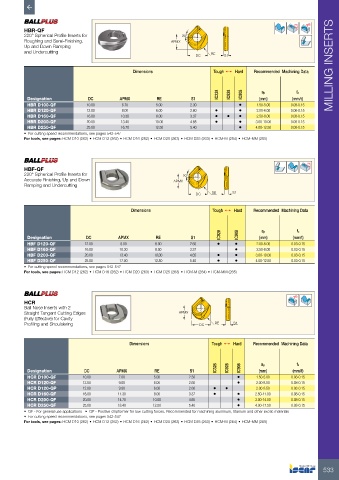

HBR-QF

220° Spherical Profile Inserts for 20°

Roughing and Semi-Finishing, APMX

Up and Down Ramping

and Undercutting RE

DC S1

Dimensions Tough 1 Hard Recommended Machining Data MILLING INSERTS

IC328 IC928 IC908 ap fz

Designation DC APMX RE S1 (mm) (mm/t)

HBR D100-QF 10.00 6.70 5.00 2.30 • 1.50-5.00 0.08-0.15

HBR D120-QF 12.00 8.00 6.00 2.60 • • 2.00-6.00 0.08-0.15

HBR D160-QF 16.00 10.30 8.00 3.37 • • • 2.50-8.00 0.08-0.15

HBR D200-QF 20.00 13.40 10.00 4.65 • • 3.00-10.00 0.08-0.15

HBR D250-QF 25.00 16.70 12.50 5.40 • 4.00-12.50 0.08-0.15

• For cutting speed recommendations, see pages 542-547

For tools, see pages: HCM D10 (262) • HCM D12 (262) • HCM D16 (262) • HCM D20 (263) • HCM D25 (263) • HCM-M (264) • HCM-MM (265)

Rd°

HBF-QF

220° Spherical Profile Inserts for 20°

Accurate Finishing, Up and Down APMX

Ramping and Undercutting

DC RE S1

Dimensions Tough 1 Hard Recommended Machining Data

IC928 IC908 ap fz

Designation DC APMX RE S1 (mm) (mm/t)

HBF D120-QF 12.00 8.00 6.00 2.60 • • 2.00-6.00 0.03-0.15

HBF D160-QF 16.00 10.30 8.00 3.37 • 2.50-8.00 0.03-0.15

HBF D200-QF 20.00 13.40 10.00 4.65 • • 3.00-10.00 0.03-0.15

HBF D250-QF 25.00 17.00 12.50 5.40 • • 4.00-12.50 0.03-0.15

• For cutting speed recommendations, see pages 542-547

For tools, see pages: HCM D12 (262) • HCM D16 (262) • HCM D20 (263) • HCM D25 (263) • HCM-M (264) • HCM-MM (265)

HCR

Ball Nose Inserts with 2

Straight Tangent Cutting Edges APMX

(Fully Effective) for Cavity

Profiling and Shouldering DC RE S1

Dimensions Tough 1 Hard Recommended Machining Data

IC328 IC928 IC908 ap fz

Designation DC APMX RE S1 (mm) (mm/t)

HCR D100-QF 10.00 7.00 5.00 2.30 • 1.50-5.00 0.08-0.15

HCR D120-QF 12.00 9.00 6.00 2.60 • 2.00-8.50 0.08-0.15

HCR D120-QP 12.00 9.80 6.00 2.60 • • 2.00-8.50 0.08-0.15

HCR D160-QF 16.00 11.30 8.00 3.37 • • 2.50-11.00 0.08-0.15

HCR D200-QF 20.00 14.70 10.00 4.65 • 3.00-14.00 0.08-0.15

HCR D250-QF 25.00 18.40 12.50 5.40 • 4.00-17.50 0.08-0.15

• QF - For general use applications • QP - Positive chipformer for low cutting forces. Recommended for machining aluminum, titanium and other exotic materials

• For cutting speed recommendations, see pages 542-547

For tools, see pages: HCM D10 (262) • HCM D12 (262) • HCM D16 (262) • HCM D20 (263) • HCM D25 (263) • HCM-M (264) • HCM-MM (265)

533