Page 537 - ISCAR(MILLINGCATALOG 38_2021)

P. 537

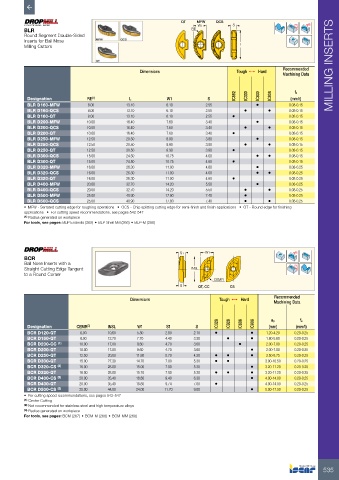

QT MFW QCS S Rd°

BLR RE W1

Round Segment Double-Sided

Inserts for Ball Nose

Milling Cutters L

Dimensions Tough 1 Hard Recommended MILLING INSERTS

Machining Data

IC882 IC330 IC830 IC808 fz

Designation RE (1) L W1 S (mm/t)

BLR D160-MFW 8.00 13.10 6.10 2.55 • 0.08-0.15

BLR D160-QCS 8.00 13.10 6.10 2.55 • • 0.08-0.15

BLR D160-QT 8.00 13.10 6.10 2.55 • 0.08-0.15

BLR D200-MFW 10.00 16.40 7.60 3.40 • 0.08-0.15

BLR D200-QCS 10.00 16.40 7.60 3.40 • • 0.08-0.15

BLR D200-QT 10.00 16.40 7.60 3.40 • 0.08-0.15

BLR D250-MFW 12.50 20.50 8.90 3.80 • 0.08-0.15

BLR D250-QCS 12.50 20.50 8.90 3.80 • • 0.08-0.15

BLR D250-QT 12.50 20.50 8.90 3.80 • 0.08-0.15

BLR D300-QCS 15.00 24.50 10.75 4.60 • • 0.08-0.15

BLR D300-QT 15.00 24.50 10.75 4.60 • 0.08-0.15

BLR D320-MFW 16.00 26.30 11.00 4.60 • 0.08-0.25

BLR D320-QCS 16.00 26.30 11.00 4.60 • • 0.08-0.25

BLR D320-QT 16.00 26.30 11.00 4.60 • 0.08-0.25

BLR D400-MFW 20.00 32.70 14.20 5.50 • 0.08-0.25

BLR D400-QCS 20.00 32.70 14.20 5.50 • • 0.08-0.25

BLR D500-MFW 25.00 40.90 17.80 7.40 • 0.08-0.25

BLR D500-QCS 25.00 40.90 17.80 7.40 • • 0.08-0.25

• MFW - Serrated cutting edge for roughing operations • QCS - Chip splitting cutting edge for semi-finish and finish applications • QT - Round edge for finishing

applications • For cutting speed recommendations, see pages 542-547

(1) Radius generated on workpiece

For tools, see pages: BLP Endmills (265) • BLP Shell Mill (266) • BLP-M (266)

S1 W1

BCR

Ball Nose Inserts with a Rd°

Straight Cutting Edge Tangent lNSL

to a Round Corner

CEMR

S QT, CC CS

Recommended

Dimensions Tough 1 Hard

Machining Data

ap

fz

Designation CEMR (3) INSL W1 S1 S IC328 IC928 IC808 IC908 (mm) (mm/t)

BCR D120-QT 6.00 10.60 5.80 2.80 2.10 • • 1.20-4.20 0.20-0.25

BCR D160-QT 8.00 12.70 7.70 4.40 3.30 • • 1.60-5.60 0.20-0.25

BCR D200-CC (1) 10.00 17.00 9.60 4.70 3.60 • 2.00-7.00 0.20-0.25

BCR D200-QT 10.00 17.00 9.60 4.70 3.60 • 2.00-7.00 0.20-0.25

BCR D250-QT 12.50 20.00 11.80 5.70 4.20 • • • 2.50-8.75 0.20-0.25

BCR D300-QT 15.00 27.30 14.70 7.00 5.30 • • 3.00-10.50 0.20-0.25

BCR D320-CS (2) 16.00 28.00 15.00 7.00 5.30 • 3.20-11.20 0.20-0.25

BCR D320-QT 16.00 28.00 15.10 7.00 5.30 • • • 3.20-11.20 0.20-0.25

BCR D400-CS (2) 20.00 35.40 18.80 9.40 6.30 • 4.00-14.00 0.20-0.25

BCR D400-QT 20.00 35.40 18.80 9.74 7.00 • 4.00-14.00 0.20-0.25

BCR D500-CS (2) 25.00 44.00 24.00 11.70 9.00 • 5.00-17.50 0.20-0.25

• For cutting speed recommendations, see pages 542-547

(1) Center Cutting

(2) Not recommended for stainless steel and high temperature alloys

(3) Radius generated on workpiece

For tools, see pages: BCM (267) • BCM-M (268) • BCM-MM (268)

535