Page 539 - ISCAR(MILLINGCATALOG 38_2021)

P. 539

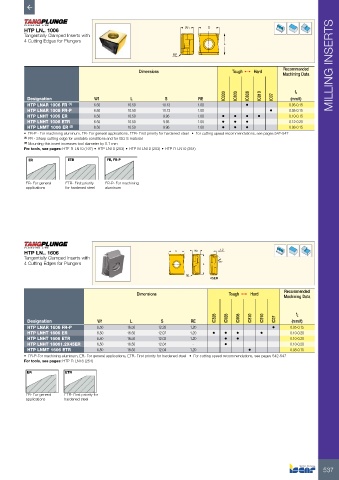

HTP LN.. 1006 W1 S

Tangentially Clamped Inserts with

4 Cutting Edges for Plungers

L

RE

Dimensions Tough 1 Hard Recommended MILLING INSERTS

Machining Data

IC330 IC830 IC808 IC810 fz

Designation W1 L S RE IC07 (mm/t)

HTP LNAR 1006 FR (1) 6.50 10.50 10.13 1.00 • 0.05-0.15

HTP LNAR 1006 FR-P 6.50 10.50 10.13 1.00 • 0.05-0.15

HTP LNHT 1006 ER 6.50 10.50 9.93 1.00 • • • • 0.10-0.15

HTP LNHT 1006 ETR 6.50 10.50 9.93 1.00 • • • 0.12-0.20

HTP LNMT 1006 ER (2) 6.50 10.50 9.96 1.00 • • • 0.08-0.15

• FR-P - For machining aluminum, ER- For general applications, ETR- First priority for hardened steel • For cutting speed recommendations, see pages 542-547

(1) FR - Sharp cutting edge for unstable conditions and for ISO S material

(2) Mounting this insert increases tool diameter by 0.1 mm

For tools, see pages: HTF-R-LN10 (197) • HTP-LN10 (253) • HTP-M-LN10 (253) • HTP-R-LN10 (254)

ER ETR FR, FR-P

ER- For general ETR- First priority FR-P- For machining

applications for hardened steel aluminum

HTP LN.. 1606 S W1 1.2

Tangentially Clamped Inserts with

4 Cutting Edges for Plungers L 45°

RE

45ER

Recommended

Dimensions Tough 1 Hard

Machining Data

IC328 IC928 IC908 IC810 IC910 fz

Designation W1 L S RE IC07 (mm/t)

HTP LNAR 1606 FR-P 6.50 16.50 12.28 1.20 • 0.05-0.15

HTP LNHT 1606 ER 6.50 16.50 12.07 1.20 • • • • 0.10-0.20

HTP LNHT 1606 ETR 6.50 16.50 12.03 1.20 • • 0.10-0.20

HTP LNHT 16061.2X45ER 6.50 16.50 12.04 - • 0.10-0.20

HTP LNMT 1606 ETR 6.50 16.50 12.04 1.20 • 0.08-0.15

• FR-P-For machining aluminum, ER- For general applications, ETR- First priority for hardened steel • For cutting speed recommendations, see pages 542-547

For tools, see pages: HTP-R-LN16 (254)

ER ETR

ER- For general ETR- First priority for

applications hardened steel

537