Page 707 - ISCAR(MILLINGCATALOG 38_2021)

P. 707

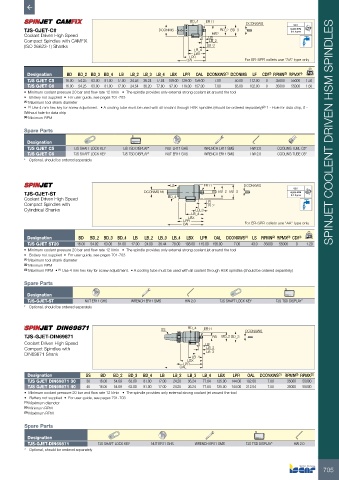

BD_4 ER11 DCONXWS

G2.5

TJS-GJET-C# DCONMS BD_2 BD_3 60,000 RPM

U<1.0 gmm

Coolant Driven High Speed BD

Compact Spindles with CAMFIX LB

LB_2

(ISO 26623-1) Shanks LB_3

LB_4

LBX

LPR

OAL For ER-SPR collets use "AA" type only

kg

Designation BD BD_2 BD_3 BD_4 LB LB_2 LB_3 LB_4 LBX LPR OAL DCONXWS (1) DCONMS LF CDI (2) RPMN (3) RPMX (4)

TJS GJET C5 16.00 54.25 63.00 81.00 17.00 24.58 36.24 77.84 109.00 129.00 159.00 7.00 50.00 112.00 0 35000 55000 1.50

TJS GJET C6 16.00 54.25 63.00 81.00 17.00 24.54 36.20 77.80 97.00 119.00 157.00 7.00 63.00 102.00 0 35000 55000 1.60

• Minimum coolant pressure 20 bar and flow rate 12 l/min • The spindle provides only external strong coolant jet around the tool

• Battery not supplied • For user guide, see pages 701-703

(1) Maximum tool shank diameter

• (1) Use 4 mm hex key for screw adjustment. • A cooling tube must be used with all coolant through HSK spindles (should be ordered separately) (2) 1 - Hole for data chip, 0 -

Without hole for data chip

(3) Minimum RPM

Spare Parts SPINJET COOLENT DRIVEN HSM SPINDLES

Designation

TJS GJET C5 TJS SHAFT LOCK KEY TJS TSD DISPLAY* NUT ER11 GHS WRENCH ER11 SMS HW 2.0 COOLING TUBE C5*

TJS GJET C6 TJS SHAFT LOCK KEY TJS TSD DISPLAY* NUT ER11 GHS WRENCH ER11 SMS HW 2.0 COOLING TUBE C6*

* Optional, should be ordered separately

LS ER11 DCONXWS G2.5

TJS-GJET-ST DCONMS h6 BD BD_2 BD_3 60,000 RPM

U<1.0 gmm

Coolant Driven High Speed BD_4

Compact Spindles with LB

LB_2

Cylindrical Shanks LB_3

LB_4

LBX

LPR

OAL For ER-SPR collets use "AA" type only

Designation BD BD_2 BD_3 BD_4 LB LB_2 LB_3 LB_4 LBX LPR OAL DCONXWS (1) LS RPMN (2) RPMX (3) CDI (4) kg

TJS GJET ST20 16.00 54.92 63.00 81.00 17.00 24.00 36.44 78.00 108.00 115.00 158.00 7.00 43.0 35000 55000 0 1.20

• Minimum coolant pressure 20 bar and flow rate 12 l/min • The spindle provides only external strong coolant jet around the tool

• Battery not supplied • For user guide, see pages 701-703

(1) Maximum tool shank diameter

(2) Minimum RPM

(3) Maximum RPM • (1) Use 4 mm hex key for screw adjustment. • A cooling tube must be used with all coolant through HSK spindles (should be ordered separately)

Spare Parts

Designation

TJS-GJET-ST NUT ER11 GHS WRENCH ER11 SMS HW 2.0 TJS SHAFT LOCK KEY TJS TSD DISPLAY*

* Optional, should be ordered separately

SS BD_4 ER11 DCONXWS

TJS-GJET-DIN69871 BD BD_2 BD_3

Coolant Driven High Speed LB

Compact Spindles with LB_2

DIN69871 Shank LB_4 LB_3

LBX

LPR

OAL

Designation SS BD BD_2 BD_3 BD_4 LB LB_2 LB_3 LB_4 LBX LPR OAL DCONXWS (1) RPMN (2) RPMX (3)

TJS GJET DIN69871 30 30 16.00 54.69 63.00 81.00 17.00 24.20 36.24 77.84 125.00 144.00 192.00 7.00 35000 55000

TJS GJET DIN69871 40 40 16.00 54.69 63.00 81.00 17.00 24.20 36.24 77.84 125.00 144.00 212.54 7.00 35000 55000

• Minimum coolant pressure 20 bar and flow rate 12 l/min • The spindle provides only external strong coolant jet around the tool

• Battery not supplied • For user guide, see pages 701-703

(1) Maximum diameter

(2) Minimum RPM

(3) Maximum RPM

Spare Parts

Designation

TJS-GJET-DIN69871 TJS SHAFT LOCK KEY NUT ER11 GHS WRENCH ER11 SMS TJS TSD DISPLAY* HW 2.0

* Optional, should be ordered separately

705