Page 712 - ISCAR(MILLINGCATALOG 38_2021)

P. 712

USER GUIDE

AUXILARY DEVICES

Electrical Nut-Clamp Torque Control Device

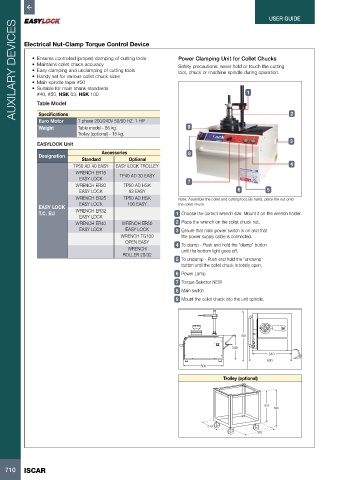

• Ensures controlled (proper) clamping of cutting tools Power Clamping Unit for Collet Chucks

• Maintains collet chuck accuracy Safety precautions: never hold or touch the cutting

• Easy clamping and unclamping of cutting tools tool, chuck or machine spindle during operation.

• Handy set for various collet chuck sizes

• Main spindle taper #50

• Suitable for main shank standards

#40, #50, HSK 63, HSK 100 1

Table Model

Specifications 2

Euro Motor 1 phase 200/240V 50/60 HZ 1 HP

Weight Table model - 85 kg. 9

Trolley (optional) - 15 kg.

3

EASYLOCK Unit

Accessories 8

Designation

Standard Optional

TP50 AD 40 EASY EASY LOCK TROLLEY 4

WRENCH ER16 TP40 AD 30 EASY

EASY LOCK 7

WRENCH ER20 TP50 AD HSK

EASY LOCK 63 EASY 6 5

WRENCH ER25 TP50 AD HSK Note: Assemble the collet and cutting tool. By hand, place the nut onto

EASY LOCK 100 EASY the collet chuck.

EASY LOCK

T.C. EU WRENCH ER32 1 Choose the correct wrench size. Mount it on the wrench holder.

EASY LOCK

WRENCH ER40 WRENCH ER50 2 Place the wrench on the collet chuck nut.

EASY LOCK EASY LOCK 3 Ensure that main power switch is on and that

WRENCH TG100 the power supply cable is connected.

OPEN EASY 4 To clamp - Push and hold the “clamp” button

WRENCH until the bottom light goes off.

ROLLER 20/32

5 To unclamp - Push and hold the “unclamp”

button until the collet chuck is totally open.

6 Power Lamp 700

7 Torque Selector NEW

340

8 Main switch

9 Mount the collet chuck into the unit spindle.

500

700

340

540

600

500

Trolley (optional)

510

630

540

600

510

550

710 ISCAR