Page 171 - ISCAR(TURNING-CATALOG-42-2022)

P. 171

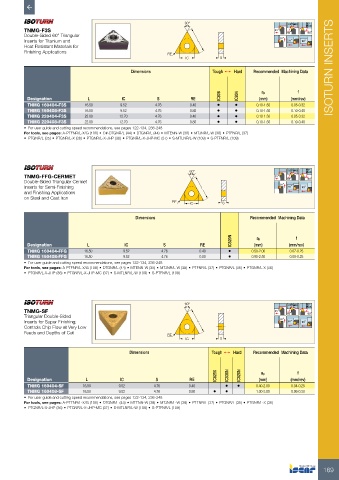

60° 22°MAX 55°

TNMG-F3S 91 º 93 º MAX

60 º

Double-Sided 60° Triangular 91 º

Inserts for Titanium and L 91 º 95 º

Heat Resistant Materials for

Finishing Applications RE

IC S

Dimensions Tough 1 Hard Recommended Machining Data ISOTURN INSERTS

IC806 IC804 ap f

Designation L IC S RE (mm) (mm/rev)

TNMG 160404-F3S 16.50 9.52 4.76 0.40 • • 0.10-1.50 0.05-0.32

TNMG 160408-F3S 16.50 9.52 4.76 0.80 • • 0.10-1.50 0.10-0.40

TNMG 220404-F3S 22.00 12.70 4.76 0.40 • • 0.10-1.50 0.05-0.32

TNMG 220408-F3S 22.00 12.70 4.76 0.80 • • 0.10-1.50 0.10-0.40

• For user guide and cutting speed recommendations, see pages 122-134, 236-248

For tools, see pages: A-PTFNR/L-X/G (108) • C#-DTGNR/L (44) • DTGNR/L (44) • MTENN-W (38) • MTJNR/L-W (38) • PTFNR/L (37)

• PTGNR/L (35) • PTGNR/L-X (36) • PTGNR/L-X-JHP (36) • PTGNR/L-X-JHP-MC (37) • S-MTLNR/L-W (109) • S-PTFNR/L (109)

60° 22°MAX 55°

TNMG-FFG-CERMET 91 º 93 º MAX

60 º

Double-Sided Triangular Cermet 91 º

Inserts for Semi-Finishing L 91 º 95 º

and Finishing Applications

on Steel and Cast Iron

RE IC S

Dimensions Recommended Machining Data

IC520N ap f

Designation L IC S RE (mm) (mm/rev)

TNMG 160404-FFG 16.50 9.52 4.76 0.40 • 0.50-2.00 0.07-0.25

TNMG 160408-FFG 16.50 9.52 4.76 0.80 • 0.90-2.50 0.08-0.25

• For user guide and cutting speed recommendations, see pages 122-134, 236-248

For tools, see pages: A-PTFNR/L-X/G (108) • DTGNR/L (44) • MTENN-W (38) • MTJNR/L-W (38) • PTFNR/L (37) • PTGNR/L (35) • PTGNR/L-X (36)

• PTGNR/L-X-JHP (36) • PTGNR/L-X-JHP-MC (37) • S-MTLNR/L-W (109) • S-PTFNR/L (109)

60° 22°MAX 55°

TNMG-SF 91 º 93 º MAX

60 º

Triangular Double-Sided 91 º

Inserts for Super Finishing; L 91 º 95 º

Controls Chip Flow at Very Low

Feeds and Depths of Cut RE

IC S

Dimensions Tough 1 Hard Recommended Machining Data

IC8250 IC530N IC520N ap f

Designation L IC S RE (mm) (mm/rev)

TNMG 160404-SF 16.50 9.52 4.76 0.40 • • 0.40-2.00 0.04-0.25

TNMG 160408-SF 16.50 9.52 4.76 0.80 • • 1.00-3.00 0.06-0.30

• For user guide and cutting speed recommendations, see pages 122-134, 236-248

For tools, see pages: A-PTFNR/L-X/G (108) • DTGNR/L (44) • MTENN-W (38) • MTJNR/L-W (38) • PTFNR/L (37) • PTGNR/L (35) • PTGNR/L-X (36)

• PTGNR/L-X-JHP (36) • PTGNR/L-X-JHP-MC (37) • S-MTLNR/L-W (109) • S-PTFNR/L (109)

169