Page 178 - ISCAR(TURNING-CATALOG-42-2022)

P. 178

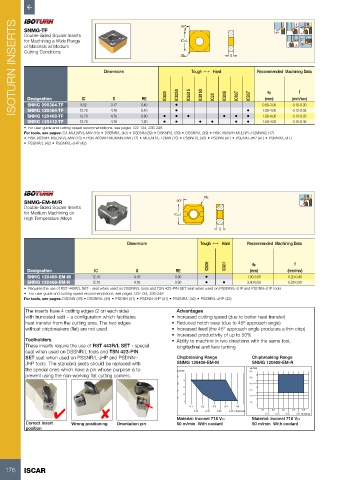

ISOTURN INSERTS SNMG-TF Dimensions IC=L Tough 1 Hard S Recommended Machining Data

45 º

90°

75 º 45 º

75 º

Double-Sided Square Inserts

for Machining a Wide Range

45°

75º

of Materials at Medium

Cutting Conditions

RE

f

ap

(mm)

S

RE

IC

Designation

SNMG 090304-TF

0.10-0.30

9.52

•

0.12-0.35

SNMG 120404-TF

0.40

4.76

1.00-4.00

•

•

1.00-4.00

SNMG 120408-TF

0.13-0.35

12.70

4.76

0.80

•

•

•

•

0.15-0.40

1.20

4.76

1.50-4.00

SNMG 120412-TF 12.70 3.17 0.40 • IC830 • IC8250 • IC6015 • IC8150 • IC20 • IC806 • IC807 • IC907 0.80-3.00 (mm/rev)

12.70

• For user guide and cutting speed recommendations, see pages 122-134, 236-248

For tools, see pages: C#-MULNR/L-MW (16) • DSBNR/L (40) • DSDNN (39) • DSKNR/L (39) • DSSNR/L (39) • HSK A63WH-MULNR-J12MWX2 (17)

• HSK A63WH-MULNR/L-MW (16) • HSK A63WH-MUMNN-MW (17) • MULNR/L-12MW (15) • PSBNR/L (43) • PSDNN (41) • PSDNN-JHP (41) • PSKNR/L (41)

• PSSNR/L (42) • PSSNR/L-JHP (42)

RE 45 º

SNMG-EM-M/R 90º 45 º

Double-Sided Square Inserts

for Medium Machining on IC=L

High Temperature Alloys

S

Dimensions Tough 1 Hard Recommended Machining Data

IC806 IC907 ap f

Designation IC S RE (mm) (mm/rev)

SNMG 120408-EM-M 12.70 4.76 0.80 • 1.00-3.00 0.20-0.40

SNMG 120408-EM-R 12.70 4.76 0.80 • • 3.00-6.00 0.25-0.50

• Requires the use of RST 443R/L SET - seat when used on DSSNR/L tools and TSN 423-PIN SET seat when used on PSSNR/L-JHP and PSDNN-JHP tools

• For user guide and cutting speed recommendations, see pages 122-134, 236-248

For tools, see pages: DSDNN (39) • DSSNR/L (39) • PSDNN (41) • PSDNN-JHP (41) • PSSNR/L (42) • PSSNR/L-JHP (42)

The inserts have 4 cutting edges (2 on each side) Advantages

with truncated radii – a configuration which facilitates • Increased cutting speed (due to better heat transfer)

heat transfer from the cutting area. The two edges • Reduced notch wear (due to 45º approach angle)

without chipbreakers (flat) are not used. • Increased feed (the 45° approach angle produces a thin chip)

• Increased productivity of up to 50%

Toolholders • Ability to machine in two directions with the same tool,

These inserts require the use of RST 443R/L SET - special longitudinal and face turning

seat when used on DSSNR/L tools and TSN 423-PIN

SET seat when used on PSSNR/L-JHP and PSDNN– Chipbreaking Range Chipbreaking Range

JHP tools. The standard seats should be replaced with SNMG 120408-EM-M SNMG 120408-EM-R

the special ones which have a pin whose purpose is to ap (mm) 6.5 ap (mm)

prevent using the non-working flat cutting corners. 4.5 5.5 6

4 5

3.5 4.5

3 4

2.5 3.5

3

2

2.5

1.5 2

1 1.5

0.1 0.2 0.3 0.4 0.5 1

0.1 0.2 0.3 0.4 0.5

0.15 0.25 0.35 0.45 f (mm/rev)

0.15 0.25 0.35 0.45 f (mm/rev)

Material: Inconel 718 Vc: Material: Inconel 718 Vc:

Correct insert Wrong positioning Orientation pin 50 m/min With coolant 50 m/min With coolant

position

176 ISCAR