Page 183 - ISCAR(TURNING-CATALOG-42-2022)

P. 183

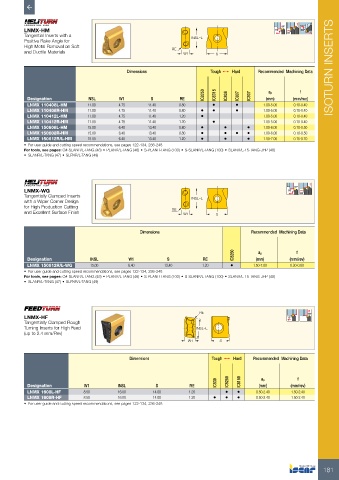

LNMX-HM 93° 91° 93 º 93º

Tangential Inserts with a INSL=L

Positive Rake Angle for

High Metal Removal on Soft RE

and Ductile Materials W1 S

Dimensions Tough 1 Hard Recommended Machining Data ISOTURN INSERTS

IC8250 IC6015 IC806 IC807 IC907 ap f

Designation INSL W1 S RE (mm) (mm/rev)

LNMX 110408L-HM 11.00 4.75 11.40 0.80 • • 1.00-5.00 0.10-0.40

LNMX 110408R-HM 11.00 4.75 11.40 0.80 • • • 1.00-5.00 0.10-0.40

LNMX 110412L-HM 11.00 4.75 11.40 1.20 • 1.00-5.00 0.10-0.40

LNMX 110412R-HM 11.00 4.75 11.40 1.20 • 1.00-5.00 0.10-0.40

LNMX 150608L-HM 15.00 6.40 13.40 0.80 • • • 1.00-6.00 0.10-0.50

LNMX 150608R-HM 15.00 6.40 13.40 0.80 • • • • 1.00-6.00 0.10-0.50

LNMX 150612R/L-HM 15.00 6.40 13.40 1.20 • • • 1.50-7.00 0.15-0.70

• For user guide and cutting speed recommendations, see pages 122-134, 236-248

For tools, see pages: C#-SLANR/L-TANG (48) • PLANR/L-TANG (46) • S-PLANR-TANG (100) • S-SLANR/L-TANG (100) • SLANR/L-15-TANG-JHP (48)

• SLANR/L-TANG (47) • SLFNR/L-TANG (49)

LNMX-WG 93° 91° 93 º

Tangentially Clamped Inserts INSL=L

with a Wiper Corner Design

for High Production Cutting RE

and Excellent Surface Finish W1 S

Dimensions Recommended Machining Data

IC8250 ap f

Designation INSL W1 S RE (mm) (mm/rev)

LNMX 150612R/L-WG 15.00 6.40 13.40 1.20 • 1.50-7.00 0.30-0.80

• For user guide and cutting speed recommendations, see pages 122-134, 236-248

For tools, see pages: C#-SLANR/L-TANG (48) • PLANR/L-TANG (46) • S-PLANR-TANG (100) • S-SLANR/L-TANG (100) • SLANR/L-15-TANG-JHP (48)

• SLANR/L-TANG (47) • SLFNR/L-TANG (49)

RE

LNMX-HF 12° 78°

Tangentially Clamped Rough

Turning Inserts for High Feed INSL=L

(up to 2.4 mm/Rev)

W1 S

Dimensions Tough 1 Hard Recommended Machining Data

IC830 IC8250 IC8150 ap f

Designation W1 INSL S RE (mm) (mm/rev)

LNMX 1608L-HF 8.50 16.00 14.00 1.20 • • 0.50-2.40 1.50-2.40

LNMX 1608R-HF 8.50 16.00 14.00 1.20 • • • 0.50-2.40 1.50-2.40

• For user guide and cutting speed recommendations, see pages 122-134, 236-248

181