Page 186 - ISCAR(TURNING-CATALOG-42-2022)

P. 186

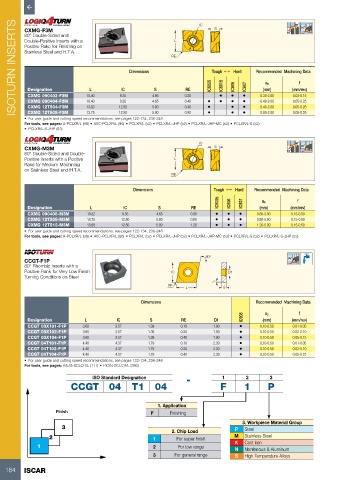

ISOTURN INSERTS CXMG-F3M L IC Dimensions S RE L RE IC IC6025 Tough 1 Hard IC807 Recommended Machining Data

95 º

95 º

S

95 º

80° Double-Sided and

Double-Positive Inserts with a

Positive Rake for Finishing on

Stainless Steel and H.T.A.

f

IC6015

ap

IC806

Designation

(mm)

(mm/rev)

CXMG 090402-F3M

9.35

10.40

4.66

•

•

•

10.40

9.35

0.40-2.00

0.40

4.65

0.05-0.25

CXMG 090404-F3M

•

•

•

12.50

13.83

5.80

0.40

0.05-0.25

0.40-2.00

CXMG 12T504-F3M

•

•

•

CXMG 12T508-F3M

0.05-0.25

13.75

0.80

0.80-2.00

12.50

5.80

• For user guide and cutting speed recommendations, see pages 122-134, 236-248 0.20 • • • • 0.30-2.00 0.03-0.15

For tools, see pages: A-PCLXR/L (99) • AVC-PCLXR/L (96) • PCLXR/L (52) • PCLXR/L-JHP (52) • PCLXR/L-JHP-MC (53) • PCLXR/L-S (52)

• PCLXR/L-S-JHP (53)

IC 95 º

CXMG-M3M S 95 º 95 º

80° Double-Sided and Double-

Positive Inserts with a Positive L

Rake for Medium Machining

on Stainless Steel and H.T.A.

RE

Dimensions Tough 1 Hard Recommended Machining Data

IC6025 IC806 IC807 ap f

Designation L IC S RE (mm) (mm/rev)

CXMG 090408-M3M 10.32 9.35 4.65 0.80 • • • 0.80-3.00 0.15-0.50

CXMG 12T508-M3M 13.75 12.50 5.80 0.80 • • • 0.80-5.00 0.15-0.50

CXMG 12T512-M3M 13.68 12.50 5.80 1.20 • • • 1.20-5.00 0.15-0.50

• For user guide and cutting speed recommendations, see pages 122-134, 236-248

For tools, see pages: A-PCLXR/L (99) • AVC-PCLXR/L (96) • PCLXR/L (52) • PCLXR/L-JHP (52) • PCLXR/L-JHP-MC (53) • PCLXR/L-S (52) • PCLXR/L-S-JHP (53)

CCGT-F1P 80° 95 º

80° Rhombic Inserts with a

Positive Flank for Very Low Finish IC D1

Turning Conditions on Steel

7°

RE

L S

Dimensions Recommended Machining Data

IC908 ap f

Designation L IC S RE D1 (mm) (mm/rev)

CCGT 03X101-F1P 3.60 3.57 1.39 0.10 1.90 • 0.10-0.50 0.01-0.05

CCGT 03X102-F1P 3.60 3.57 1.39 0.20 1.90 • 0.10-0.50 0.02-0.10

CCGT 03X104-F1P 3.60 3.57 1.39 0.40 1.90 • 0.10-0.50 0.05-0.15

CCGT 04T101-F1P 4.40 4.37 1.79 0.10 2.30 • 0.10-0.50 0.01-0.05

CCGT 04T102-F1P 4.40 4.37 1.79 0.20 2.30 • 0.10-0.50 0.02-0.10

CCGT 04T104-F1P 4.40 4.37 1.79 0.40 2.30 • 0.10-0.50 0.05-0.15

• For user guide and cutting speed recommendations, see pages 122-134, 236-248

For tools, see pages: A/E/S-SCLCR/L (111) • PICIN-SCLCR/L (386)

ISO Standard Designation - 1 2 3

CCGT 04 T1 04 F 1 P

1. Application

Finish F Finishing

3. Workpiece Material Group

3 P Steel

2. Chip Load

2 1 For super finish M Stainless Steel

1 2 For low range K Cast Iron

N

Nonferrous & Aluminum

3 For general range S High Temperature Alloys

184 ISCAR