Page 224 - ISCAR(TURNING-CATALOG-42-2022)

P. 224

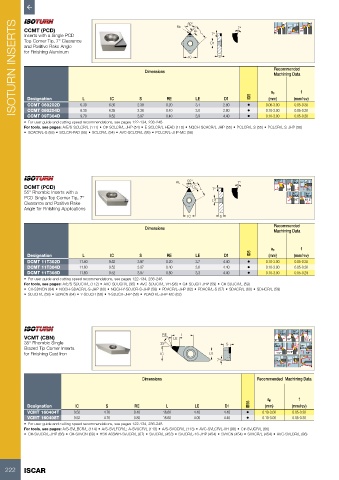

ISOTURN INSERTS CCMT (PCD) Dimensions RE 80° LE L D1 S 7° ap Recommended 91° 99°

95 º

95 º

95 º

7°

Inserts with a Single PCD

Top Corner Tip, 7° Clearance

and Positive Rake Angle

for Finishing Aluminum

IC

Machining Data

f

IC

L

Designation

S

(mm)

D1

RE

2.38

0.05-0.30

CCMT 060202D

6.30

6.35

3.1

•

0.40

6.35

2.80

6.30

0.10-3.00

2.38

3.0

0.05-0.30

CCMT 060204D

•

0.40

9.52

3.97

3.9

9.70

0.10-3.00

CCMT 09T304D

0.05-0.30

4.40

• For user guide and cutting speed recommendations, see pages 122-134, 236-248 0.20 LE 2.80 • ID5 0.08-3.00 (mm/rev)

For tools, see pages: A/E/S-SCLCR/L (111) • C#-SCLCR/L-JHP (54) • E-SCLCR/L-HEAD (110) • NQCH-SCACR/L-JHP (55) • PCLCR/L-S (55) • PCLCR/L-S-JHP (56)

• SCACR/L-S (55) • SCLCR-PAD (55) • SCLCR/L (54) • AVC-SCLCR/L (95) • PCLCR/L-JHP-MC (56)

RE 55° 107.5° 29°

DCMT (PCD) LE L 7° 7° 91° MAX 93º-95º 50º

MAX

55° Rhombic Inserts with a 27° 60°

MAX

PCD Single Top Corner Tip, 7° D1 MAX 62.5 º

93 º

Clearance and Positive Rake

Angle for Finishing Applications

IC S

Dimensions Recommended

Machining Data

ap f

Designation L IC S RE LE D1 ID5 (mm) (mm/rev)

DCMT 11T302D 11.60 9.52 3.97 0.20 3.7 4.40 • 0.10-3.00 0.05-0.30

DCMT 11T304D 11.60 9.52 3.97 0.40 3.6 4.40 • 0.10-3.00 0.05-0.30

DCMT 11T308D 11.60 9.52 3.97 0.80 3.3 4.40 • 0.10-3.00 0.05-0.29

• For user guide and cutting speed recommendations, see pages 122-134, 236-248

For tools, see pages: A/E/S-SDUCR/L (112) • AVC-SDUCR/L (95) • AVC-SDUCR/L-VH (98) • C#-SDJCR-JHP (59) • C#-SDJCR/L (59)

• C#-SDNCN (64) • NQCH-SDACR/L-S-JHP (60) • NQCH-Y-SDJCR-S-JHP (58) • PDACR/L-JHP (62) • PDACR/L-S (57) • SDACR/L (60) • SDHCR/L (59)

• SDJCR/L (58) • SDNCN (64) • Y-SDJCR (58) • Y-SDJCR-JHP (58) • PDACR/L-JHP-MC (62)

52° 50° 70°MAX

VCMT (CBN) RE LE L 91° MAX 93° MAX 72.5 º

35° Rhombic Single 35° S 31°

Brazed Tip Corner Inserts MAX 48°

MAX

for Finishing Cast Iron IC D1 112° 117.5° 95º

7° 35° 95 º

MAX

107.5º

Dimensions Recommended Machining Data

ap f

Designation IC S RE L LE D1 IB55 (mm) (mm/rev)

VCMT 160404T 9.52 4.76 0.40 16.60 4.40 4.40 • 0.10-3.00 0.05-0.30

VCMT 160408T 9.52 4.76 0.80 16.60 4.00 4.40 • 0.10-3.00 0.05-0.30

• For user guide and cutting speed recommendations, see pages 122-134, 236-248

For tools, see pages: A/S-SVLBCR/L (114) • A/S-SVLFCR/L; A-SVUCR/L (113) • A/S-SVQCR/L (113) • AVC-SVLCR/L-VH (98) • C#-SVJCR/L (66)

• C#-SVJCR/L-JHP (66) • C#-SVVCN (69) • HSK A63WH-SVJCR/L (67) • SVJCR/L (453) • SVJCR/L-16-JHP (454) • SVVCN (454) • SVXCR/L (454) • AVC-SVLCR/L (96)

222 ISCAR