Page 219 - ISCAR(TURNING-CATALOG-42-2022)

P. 219

75° 95 º

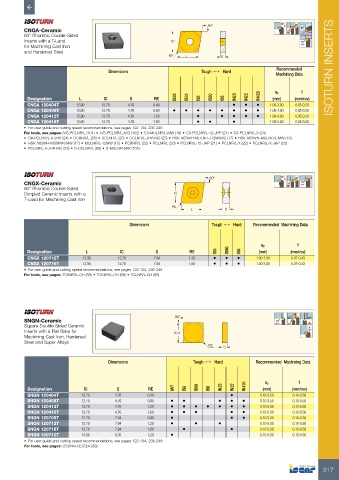

CNGA-Ceramic 80° 95 º 95 º

80° Rhombic Double-Sided

Inserts with a T-Land IC 75 º

for Machining Cast Iron

and Hardened Steel

RE L S

Dimensions Tough 1 Hard Recommended ISOTURN INSERTS

Machining Data

f

ap

Designation L IC S RE IS35 IS25 IS8 IS80 IS6 IN23 IN22 IN420 (mm) (mm/rev)

CNGA 120404T 12.90 12.70 4.76 0.40 • • • 1.00-3.00 0.05-0.20

CNGA 120408T 12.90 12.70 4.76 0.80 • • • • • • • • 1.00-4.00 0.05-0.20

CNGA 120412T 12.90 12.70 4.76 1.20 • • • • • 1.00-4.00 0.05-0.20

CNGA 120416T 12.90 12.70 4.76 1.60 • • • 1.00-5.00 0.05-0.20

• For user guide and cutting speed recommendations, see pages 122-134, 236-248

For tools, see pages: A/S-PCLNR/L (101) • A/S-PCLNR/L-X/G (102) • C#-MULNR/L-MW (16) • C#-PCLNR/L-12-JHP (21) • C#-PCLNR/L-X (24)

• C#-PCLNR/L-X-JHP (24) • DCBNR/L (26) • DCLNR/L (25) • DCLNR/L-JHP-MC (25) • HSK A63WH-MULNR-J12MWX2 (17) • HSK A63WH-MULNR/L-MW (16)

• HSK A63WH-MUMNN-MW (17) • MULNR/L-12MW (15) • PCBNR/L (22) • PCLNR/L (20) • PCLNR/L-12-JHP (21) • PCLNR/L-X (22) • PCLNR/L-X-JHP (23)

• PCLNR/L-X-JHP-MC (23) • S-DCLNR/L (99) • S-MULNR-MW (105)

80° 75° 95 º

CNGX-Ceramic 95 º 75 º

80° Rhombic Double-Sided

Dimpled Ceramic Inserts with a IC

T-Land for Machining Cast Iron

RE

L S

Dimensions Tough 1 Hard Recommended Machining Data

ap f

Designation L IC S RE IS8 IS80 IS6 (mm) (mm/rev)

CNGX 120712T 12.90 12.70 7.94 1.20 • • • 1.00-3.00 0.07-0.43

CNGX 120716T 12.90 12.70 7.94 1.60 • • • 1.00-3.00 0.07-0.43

• For user guide and cutting speed recommendations, see pages 122-134, 236-248

For tools, see pages: TCBNR/L-CH (88) • TCKNR/L-CH (88) • TCLNR/L-CH (88)

45 º

SNGN-Ceramic 90° 75 º 45 º 45°

Square Double-Sided Ceramic

Inserts with a Flat Rake for IC=L 75 º

Machining Cast Iron, Hardened

Steel and Super Alloys

RE S

Dimensions Tough 1 Hard Recommended Machining Data

f

ap

Designation IC S RE IW7 IS8 IS80 IS6 IN23 IN22 IN420 (mm) (mm/rev)

SNGN 120404T 12.70 4.76 0.40 • 0.10-3.50 0.10-0.50

SNGN 120408T 12.70 4.76 0.80 • • • • • 0.10-3.50 0.10-0.50

SNGN 120412T 12.70 4.76 1.20 • • • • • • • 0.10-5.00 0.10-0.50

SNGN 120416T 12.70 4.76 1.60 • • • • • 0.10-5.00 0.10-0.50

SNGN 120708T 12.70 7.94 0.80 • • • 0.10-5.00 0.10-0.50

SNGN 120712T 12.70 7.94 1.20 • • • 0.10-5.00 0.10-0.50

SNGN 120716T 12.70 7.94 1.60 • • 0.10-5.00 0.10-0.50

SNGN 150712T 15.88 6.35 1.20 • 0.10-5.00 0.10-0.50

• For user guide and cutting speed recommendations, see pages 122-134, 236-248

For tools, see pages: CSDNN-CE/CEA (89)

217