Page 222 - ISCAR(TURNING-CATALOG-42-2022)

P. 222

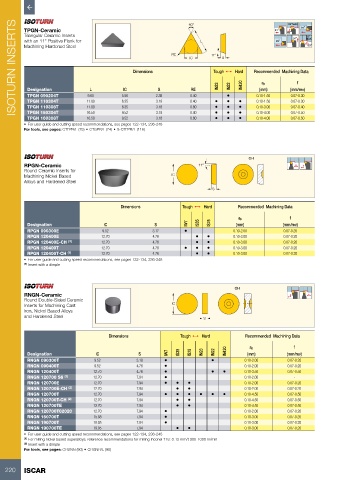

ISOTURN INSERTS TPGN-Ceramic L IC Dimensions S RE 60° L 11° Tough 1 Hard IN420 Recommended Machining Data 60 º

22°MAX

91 º

91 º

93 º

Triangular Ceramic Inserts

55°

91 º

MAX

with an 11° Positive Flank for

95 º

Machining Hardened Steel

S

IC

f

ap

IN22

IN23

RE

Designation

(mm/rev)

(mm)

TPGN 090204T

9.60

•

0.07-0.30

0.10-1.50

0.40

3.18

6.35

TPGN 110304T

•

•

•

0.07-0.40

11.00

3.18

6.35

0.10-3.00

TPGN 110308T

0.80

•

•

•

TPGN 160304T

0.07-0.50

16.50

0.10-4.00

0.40

9.52

3.18

•

•

•

TPGN 160308T 11.00 5.56 2.38 0.40 • • • 0.10-1.50 0.07-0.30

3.18

0.10-4.00

9.52

0.80

16.50

0.07-0.50

• For user guide and cutting speed recommendations, see pages 122-134, 236-248

For tools, see pages: CTFPR/L (75) • CTGPR/L (74) • S-CTFPR/L (116)

CH

RPGN-Ceramic 11°

Round Ceramic Inserts for

Machining Nickel Based IC

Alloys and Hardened Steel

S

Dimensions Tough 1 Hard Recommended Machining Data

ap f

Designation IC S IW7 IS35 IS25 (mm) (mm/rev)

RPGN 090300E 9.52 3.17 • 0.10-2.00 0.07-0.20

RPGN 120400E 12.70 4.76 • • 0.10-3.00 0.07-0.20

RPGN 120400E-CH (1) 12.70 4.76 • • 0.10-3.00 0.07-0.20

RPGN 120400T 12.70 4.76 • • • 0.10-3.00 0.07-0.20

RPGN 120400T-CH (1) 12.70 4.76 • • 0.10-3.00 0.07-0.20

• For user guide and cutting speed recommendations, see pages 122-134, 236-248

(1) Insert with a dimple

CH

RNGN-Ceramic

Round Double-Sided Ceramic

Inserts for Machining Cast IC

Iron, Nickel Based Alloys

and Hardened Steel S

Dimensions Tough 1 Hard Recommended Machining Data

f

ap

Designation IC S IW7 IS35 IS25 IN23 IN22 IN420 (mm) (mm/rev)

RNGN 090300T 9.52 3.18 • • 0.10-2.00 0.07-0.20

RNGN 090400T 9.52 4.76 • 0.10-2.00 0.07-0.20

RNGN 120400T 12.70 4.76 • • • 0.10-3.50 0.07-0.50

RNGN 120700 S6 (1) 12.70 7.94 • 0.10-2.00 -

RNGN 120700E 12.70 7.94 • • • 0.10-2.00 0.07-0.20

RNGN 120700E-CH (2) 12.70 7.94 • • 0.10-2.00 0.07-0.20

RNGN 120700T 12.70 7.94 • • • • • • 0.10-4.50 0.07-0.50

RNGN 120700T-CH (2) 12.70 7.94 • • 0.10-4.50 0.07-0.50

RNGN 120700TE 12.70 7.94 • • 0.10-4.50 0.07-0.50

RNGN 120700T02020 12.70 7.94 • 0.10-2.00 0.07-0.20

RNGN 150700T 15.88 7.94 • 0.10-3.00 0.07-0.20

RNGN 190700T 19.05 7.94 • 0.10-3.00 0.07-0.20

RNGN 190700TE 19.05 7.94 • • 0.10-3.00 0.07-0.20

• For user guide and cutting speed recommendations, see pages 122-134, 236-248

(1) For milling nickel based superalloys; reference recommendations for milling Inconel 718: 0.12 mm/t 900-1000 m/min

(2) Insert with a dimple

For tools, see pages: CRDNN (90) • CRGNR/L (90)

220 ISCAR