Page 494 - ISCAR(TURNING-CATALOG-42-2022)

P. 494

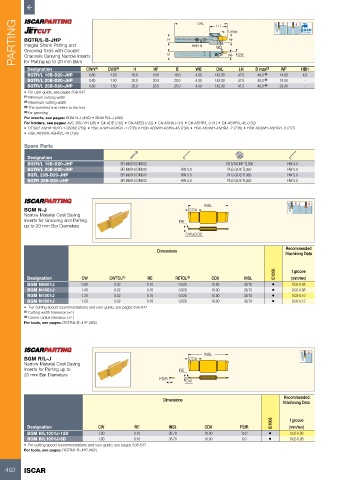

PARTING BGTR/L-B-JHP H HBH OAL LH WF CW Bar Max

Dmax

HF

Integral Shank Parting and

WB

Grooving Tools with Coolant

B

Channels Carrying Narrow Inserts

for Parting up to 20 mm Bars

Designation CWN (1) CWX (2) H HF B WB OAL LH D max (3) WF HBH

BGTR/L 16B-D20-JHP 0.80 1.50 16.0 16.0 16.0 4.00 142.00 47.5 40.0 (4) 14.00 4.0

BGTR/L 20B-D20-JHP 0.80 1.50 20.0 20.0 20.0 4.00 142.00 47.5 40.0 18.00 -

(4)

(4)

BGTR/L 25B-D20-JHP 0.80 1.50 25.0 25.0 25.0 4.00 142.00 47.5 40.0 23.00 -

• For user guide, see pages 538-547

(1) Minimum cutting width

(2) Maximum cutting width

(3) The specified limit refers to the tool

(4) for grooving

For inserts, see pages: BGM N-J (492) • BGM R/L-J (492)

For holders, see pages: AVC-D80-VH (98) • C#-ADE (732) • C#-ADES (732) • C#-ASHA (731) • C#-ASHR/L (731) • C#-ASHR/L-45 (732)

• DT30/2 ASH# 16/20-1-35080 (759) • HSK A-WH-ASHR/L-1 (736) • HSK A63WH-ASHN-45 (736) • HSK A63WH-ASHR/L-2 (736) • HSK A63WH-ASHR/L-3 (737)

• HSK A63WH-ASHR/L-45 (736)

Spare Parts

Designation

BGTR/L 16B-D20-JHP SR M5X16 DIN912 SR 5/16UNF TL360 HW 4.0

BGTR/L 20B-D20-JHP SR M5X16 DIN912 HW 3.0 PLG G1/8 TL360 HW 5.0

BGTL 25B-D20-JHP SR M5X16 DIN912 HW 3.0 PLG G1/8 TL360 HW 5.0

BGTR 25B-D20-JHP SR M5X16 DIN912 HW 4.0 PLG G1/8 TL360 HW 5.0

BGM N-J CDX INSL

Narrow Material Cost Saving

Inserts for Grooving and Parting RE

up to 20 mm Bar Diameters

CW±0.02

Recommended

Dimensions

Machining Data

IC1008 f groove

Designation CW CWTOL (1) RE RETOL (2) CDX INSL (mm/rev)

BGM N0801J 0.80 0.02 0.10 0.020 10.00 38.70 • 0.02-0.05

BGM N1001J 1.00 0.02 0.10 0.020 10.00 38.70 • 0.02-0.08

BGM N1201J 1.20 0.02 0.10 0.020 10.00 38.70 • 0.03-0.10

BGM N1501J 1.50 0.02 0.10 0.020 10.00 38.70 • 0.05-0.12

• For cutting speed recommendations and user guide, see pages 538-547

(1) Cutting width tolerance (+/-)

(2) Corner radius tolerance (+/-)

For tools, see pages: BGTR/L-B-JHP (492)

BGM R/L-J CDX INSL

Narrow Material Cost Saving

Inserts for Parting up to RE

20 mm Bar Diameters

PSIR CW

Recommended

Dimensions

Machining Data

IC1008 f groove

Designation CW RE INSL CDX PSIR (mm/rev)

BGM R/L1001J-15D 1.00 0.10 38.70 10.00 15.0 • 0.02-0.06

BGM R/L1001J-6D 1.00 0.10 38.70 10.00 6.0 • 0.02-0.08

• For cutting speed recommendations and user guide, see pages 538-547

For tools, see pages: BGTR/L-B-JHP (492)

492 ISCAR