Page 492 - ISCAR(TURNING-CATALOG-42-2022)

P. 492

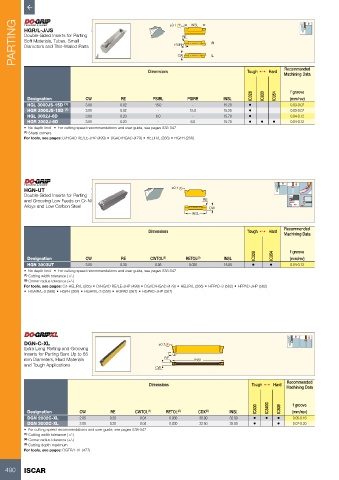

PARTING HGR/L-J/JS ±0.1 PSIRR RE lNSL R L

Double-Sided Inserts for Parting

Soft Materials, Tubes, Small

Diameters and Thin-Walled Parts

CW

Dimensions Tough 1 Hard Recommended

Machining Data

f groove

IC328 IC830 IC354

Designation CW RE PSIRL PSIRR INSL (mm/rev)

HGL 3000JS-15D (1) 3.00 0.02 15.0 - 15.20 • 0.03-0.07

HGR 3000JS-15D (1) 3.00 0.02 - 15.0 15.20 • 0.03-0.07

HGL 3002J-6D 3.00 0.20 6.0 - 15.70 • 0.04-0.12

HGR 3002J-6D 3.00 0.20 - 6.0 15.70 • • • 0.04-0.12

• No depth limit • For cutting speed recommendations and user guide, see pages 538-547

(1) Sharp corners

For tools, see pages: D/HGAD RE/LE-JHP (499) • DGAD/HGAD (479) • HELIR/L (266) • HGFH (268)

HGN-UT ±0.1

Double-Sided Inserts for Parting

and Grooving Low Feeds on Cr-Ni RE

Alloys and Low Carbon Steel CW

INSL

Recommended

Dimensions Tough 1 Hard

Machining Data

IC328 IC354 f groove

Designation CW RE CWTOL (1) RETOL (2) INSL (mm/rev)

HGN 3003UT 3.00 0.30 0.05 0.030 15.80 • • 0.04-0.13

• No depth limit • For cutting speed recommendations and user guide, see pages 538-547

(1) Cutting width tolerance (+/-)

(2) Corner radius tolerance (+/-)

For tools, see pages: C#-HELIR/L (265) • D/HGAD RE/LE-JHP (499) • DGAD/HGAD (479) • HELIR/L (266) • HFPAD-3 (562) • HFPAD-JHP (562)

• HGAIR/L-3 (568) • HGFH (268) • HGHR/L-3 (558) • HGPAD (267) • HGPAD-JHP (267)

DGN-C-XL ±0.1

Extra Long Parting and Grooving

Inserts for Parting Bars Up to 65 7°

mm Diameters, Hard Materials RE INSL

and Tough Applications

CW

Recommended

Dimensions Tough 1 Hard

Machining Data

IC830 IC5400 IC808 f groove

Designation CW RE CWTOL (1) RETOL (2) CDX (3) INSL (mm/rev)

DGN 2002C-XL 2.05 0.20 0.04 0.030 30.00 32.00 • • • 0.05-0.16

DGN 3002C-XL 3.00 0.20 0.04 0.030 32.50 35.00 • • 0.07-0.20

• For cutting speed recommendations and user guide, see pages 538-547

(1) Cutting width tolerance (+/-)

(2) Corner radius tolerance (+/-)

(3) Cutting depth maximum

For tools, see pages: DGTR/L-XL (477)

490 ISCAR