Page 490 - ISCAR(TURNING-CATALOG-42-2022)

P. 490

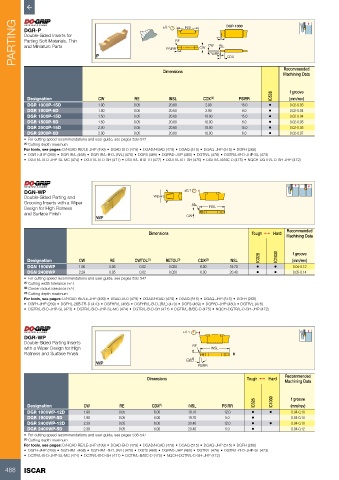

PARTING DGR-P ±0.1 RE lNSL CW CW 7° RE DGR 1000

Double-Sided Inserts for

Parting Soft Materials, Thin

and Miniature Parts

PSIRR

PSIRR

CDX

Dimensions Recommended

Machining Data

IC508 f groove

Designation CW RE INSL CDX (1) PSIRR (mm/rev)

DGR 1000P-15D 1.00 0.05 20.60 2.90 15.0 • 0.02-0.03

DGR 1000P-6D 1.00 0.05 20.60 2.90 6.0 • 0.02-0.04

DGR 1500P-15D 1.50 0.05 20.60 18.00 15.0 • 0.02-0.04

DGR 1500P-6D 1.50 0.05 20.60 18.00 6.0 • 0.02-0.05

DGR 2000P-15D 2.00 0.05 20.60 18.00 15.0 • 0.02-0.05

DGR 2000P-6D 2.00 0.05 20.60 18.00 6.0 • 0.02-0.07

• For cutting speed recommendations and user guide, see pages 538-547

(1) Cutting depth maximum

For tools, see pages: D/HGAD RE/LE-JHP (499) • DGAD-B-D (479) • DGAD/HGAD (479) • DGAQ (515) • DGAQ-JHP (515) • DGFH (268)

• DGFH-JHP (269) • DGFHR/L (468) • DGFHR/L-B-D..(R/L) (470) • DGFS (469) • DGPAD-JHP (480) • DGTR/L (476) • DGTR/L-B-D-JHP-SL (473)

• DGTR/L-B-D-JHP-SL-MC (474) • DGTR/L-B-D-SH (471) • DGTR/L-B-D-TR (477) • DGTR/L-B-T-SH (476) • DGTR/L-B/BC-D (475) • NQCH-DGTR/L-D-SH-JHP (472)

DGN-WP ±0.1

Double-Sided Parting and Wipers

Grooving Inserts with a Wiper RE

Design for High Flatness INSL

and Surface Finish

CW

Recommended

Dimensions Tough 1 Hard

Machining Data

f groove

Designation CW RE CWTOL (1) RETOL (2) CDX (3) INSL IC328 IC1030 (mm/rev)

DGN 1900WP 1.90 0.05 0.02 0.020 6.00 19.70 • • 0.04-0.12

DGN 2400WP 2.39 0.05 0.02 0.020 6.00 20.40 • • 0.05-0.14

• For cutting speed recommendations and user guide, see pages 538-547

(1) Cutting width tolerance (+/-)

(2) Corner radius tolerance (+/-)

(3) Cutting depth maximum

For tools, see pages: D/HGAD RE/LE-JHP (499) • DGAD-B-D (479) • DGAD/HGAD (479) • DGAQ (515) • DGAQ-JHP (515) • DGFH (268)

• DGFH-JHP (269) • DGFHL-26B-TR-D (470) • DGFHR/L (468) • DGFHR/L-B-D..(R/L) (470) • DGFS (469) • DGPAD-JHP (480) • DGTR/L (476)

• DGTR/L-B-D-JHP-SL (473) • DGTR/L-B-D-JHP-SL-MC (474) • DGTR/L-B-D-SH (471) • DGTR/L-B/BC-D (475) • NQCH-DGTR/L-D-SH-JHP (472)

±0.1

DGR-WP

Double-Sided Parting Inserts

with a Wiper Design for High RE INSL

Flatness and Surface Finish R

CW

PSIRR

Recommended

Dimensions Tough 1 Hard

Machining Data

IC328 IC1030 f groove

Designation CW RE CDX (1) INSL PSIRR (mm/rev)

DGR 1900WP-12D 1.90 0.05 6.00 19.70 12.0 • • 0.04-0.10

DGR 1900WP-5D 1.90 0.05 6.00 19.70 5.0 • 0.04-0.10

DGR 2400WP-12D 2.39 0.05 6.00 20.40 12.0 • • 0.04-0.10

DGR 2400WP-5D 2.39 0.05 6.00 20.40 5.0 • 0.04-0.12

• For cutting speed recommendations and user guide, see pages 538-547

(1) Cutting depth maximum

For tools, see pages: D/HGAD RE/LE-JHP (499) • DGAD-B-D (479) • DGAD/HGAD (479) • DGAQ (515) • DGAQ-JHP (515) • DGFH (268)

• DGFH-JHP (269) • DGFHR/L (468) • DGFHR/L-B-D..(R/L) (470) • DGFS (469) • DGPAD-JHP (480) • DGTR/L (476) • DGTR/L-B-D-JHP-SL (473)

• DGTR/L-B-D-JHP-SL-MC (474) • DGTR/L-B-D-SH (471) • DGTR/L-B/BC-D (475) • NQCH-DGTR/L-D-SH-JHP (472)

488 ISCAR