Page 584 - ISCAR(TURNING-CATALOG-42-2022)

P. 584

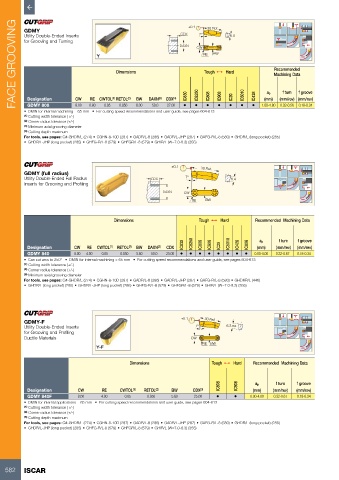

FACE GROOVING GDMY Dimensions DAXN ±0.1 CW RE 30 Ref. 6.4 Machining Data

7°

CDX

Utility Double-Ended Inserts

for Grooving and Turning

BW

Recommended

Tough 1 Hard

IC8250

f turn

f groove

IC830

IC808

ap

CWTOL RETOL

(1)

(2)

Designation

CW

RE

CDX

(4)

(mm)

BW

DAXN

(3)

•

•

•

0.80

8.00

27.00

0.05

6.00

50.0

0.050

GDMY 808

0.18-0.34

0.32-0.56

• DMIN for internal machining = 65 mm • For cutting speed recommendations and user guide, see pages 604-613 • IC908 • IC20 • IC5010 • IC428 1.00-4.80 (mm/rev) (mm/rev)

(1) Cutting width tolerance (+/-)

(2) Corner radius tolerance (+/-)

(3) Minimum axial grooving diameter

(4) Cutting depth maximum

For tools, see pages: C#-GHDR/L (274) • CGHN-8-10D (287) • GADR/L-8 (286) • GADR/L-JHP (287) • GAFG-R/L-8 (580) • GHDR/L (long pocket) (285)

• GHDR/L-JHP (long pocket) (285) • GHFG-R/L-8 (579) • GHFGR/L-8 (579) • GHIR/L (W=7.0-8.3) (355)

±0.1

GDMY (full radius) 30 Ref.

Utility Double-Ended Full Radius CDX 7° 6.4

Inserts for Grooving and Profiling

DAXN CW

RE BW

Dimensions Tough 1 Hard Recommended Machining Data

f groove

f turn

ap

Designation CW RE CWTOL (1) RETOL (2) BW DAXN (3) CDX IC830 IC8250 IC808 IC908 IC20 IC5010 IC428 IC806 (mm) (mm/rev) (mm/rev)

GDMY 840 8.00 4.00 0.05 0.050 5.60 50.0 25.00 • • • • • • • • 0.00-4.00 0.32-0.67 0.18-0.34

• Can cut arcs to 250° • DMIN for internal machining = 65 mm • For cutting speed recommendations and user guide, see pages 604-613

(1) Cutting width tolerance (+/-)

(2) Corner radius tolerance (+/-)

(3) Minimum axial grooving diameter

For tools, see pages: C#-GHDR/L (274) • CGHN-8-10D (287) • GADR/L-8 (286) • GADR/L-JHP (287) • GAFG-R/L-8 (580) • GHDKR/L (446)

• GHDR/L (long pocket) (285) • GHDR/L-JHP (long pocket) (285) • GHFG-R/L-8 (579) • GHFGR/L-8 (579) • GHIR/L (W=7.0-8.3) (355)

GDMY-F ±0.1 30 Ref.

Utility Double-Ended Inserts 7º 6.3 Ref.

for Grooving and Profiling

Ductile Materials CW

RE BW

Dimensions Tough 1 Hard Recommended Machining Data

IC808 IC908 ap f turn f groove

Designation CW RE CWTOL (1) RETOL (2) BW CDX (3) (mm) (mm/rev) (mm/rev)

GDMY 840F 8.00 4.00 0.05 0.050 5.60 25.00 • • 0.00-4.00 0.32-0.67 0.18-0.34

• DMIN for internal applications = 65 mm • For cutting speed recommendations and user guide, see pages 604-613

(1) Cutting width tolerance (+/-)

(2) Corner radius tolerance (+/-)

(3) Cutting depth maximum

For tools, see pages: C#-GHDR/L (274) • CGHN-8-10D (287) • GADR/L-8 (286) • GADR/L-JHP (287) • GAFG-R/L-8 (580) • GHDR/L (long pocket) (285)

• GHDR/L-JHP (long pocket) (285) • GHFG-R/L-8 (579) • GHFGR/L-8 (579) • GHIR/L (W=7.0-8.3) (355)

582 ISCAR