Page 580 - ISCAR(TURNING-CATALOG-42-2022)

P. 580

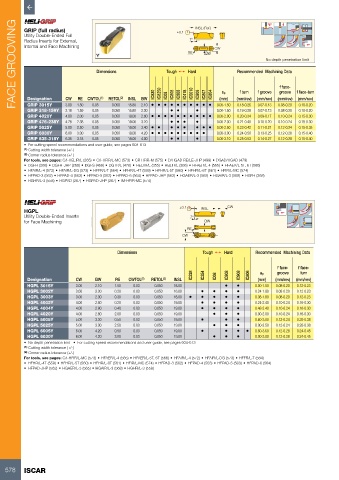

FACE GROOVING GRIP (full radius) Dimensions Tough 1 Hard INSL (Ref.) CW Recommended Machining Data

±0.1

Utility Double-Ended Full

7°

Radius Inserts for External,

Internal and Face Machining

RE

BW

No depth penetration limit

f face-

f groove

groove

f turn

IC808

ap

(mm/rev)

Designation

RE

(mm)

2.10 • • • • • • • • • •

0.18-0.26

GRIP 3015Y

0.07-0.13

15.80

3.00

0.050

0.08-0.20

0.10-0.20

0.05

3.18

0.07-0.13

0.19-0.28

0.00-1.50

0.050

0.05

0.08-0.20

0.10-0.20

2.30

15.80

1.59

GRIP 318-159Y CW 1.50 CWTOL (1) RETOL (2) INSL BW IC830 IC8250 IC08 • • IC908 IC418 IC5010 • IC806 IC807 IC804 0.00-1.50 (mm/rev) (mm/rev) (mm/rev) f face-turn

GRIP 4020Y 4.00 2.00 0.05 0.050 19.00 2.80 • • • • • • • • • • 0.00-2.00 0.20-0.34 0.09-0.17 0.10-0.24 0.15-0.30

GRIP 476-238Y 4.76 2.38 0.05 0.050 19.00 3.20 • • • • 0.00-2.30 0.21-0.40 0.10-0.20 0.10-0.24 0.15-0.30

GRIP 5025Y 5.00 2.50 0.05 0.050 19.00 3.40 • • • • • • • • 0.00-2.50 0.23-0.42 0.11-0.21 0.12-0.24 0.15-0.35

GRIP 6030Y 6.00 3.00 0.05 0.050 19.00 4.20 • • • • • • • • • 0.00-3.00 0.24-0.50 0.13-0.25 0.12-0.28 0.15-0.40

GRIP 635-318Y 6.35 3.18 0.05 0.050 19.00 4.00 • • • 0.00-3.10 0.25-0.53 0.14-0.27 0.12-0.28 0.15-0.40

• For cutting speed recommendations and user guide, see pages 604-613

(1) Cutting width tolerance (+/-)

(2) Corner radius tolerance (+/-)

For tools, see pages: C#-HELIR/L (265) • C#-HFIR/L-MC (573) • CR HFIR-M (575) • D/HGAD RE/LE-JHP (499) • DGAD/HGAD (479)

• DGFH (268) • DGFH-JHP (269) • DGFS (469) • DGTR/L (476) • HELIIR/L (355) • HELIR/L (266) • HFAER/L-4 (565) • HFAER/L-5T, 6T (566)

• HFAIR/L-4 (572) • HFAIR/L-DG (573) • HFFR/L-T (564) • HFHR/L-4T (559) • HFHR/L-5T (560) • HFHR/L-6T (561) • HFIR/L-MC (574)

• HFPAD-3 (562) • HFPAD-4 (563) • HFPAD-5 (563) • HFPAD-6 (564) • HFPAD-JHP (562) • HGAER/L-3 (565) • HGAIR/L-3 (568) • HGFH (268)

• HGHR/L-3 (558) • HGPAD (267) • HGPAD-JHP (267) • IM-HFIR-MC (574)

HGPL ±0.1 INSL CW

Utility Double-Ended Inserts 7°

for Face Machining BW

RE

CW

Dimensions Tough 1 Hard Recommended Machining Data

f face- f face-

IC328 IC354 IC08 IC808 IC908 IC806 ap groove turn

Designation CW BW RE CWTOL (1) RETOL (2) INSL (mm) (mm/rev) (mm/rev)

HGPL 3015Y 3.00 2.10 1.50 0.03 0.050 16.00 • • 0.00-1.50 0.08-0.20 0.12-0.23

HGPL 3002Y 3.00 2.30 0.20 0.03 0.050 16.00 • • • • 0.24-1.80 0.08-0.20 0.12-0.23

HGPL 3003Y 3.00 2.30 0.30 0.03 0.050 16.00 • • • • • 0.36-1.80 0.08-0.20 0.12-0.23

HGPL 4002Y 4.00 2.80 0.20 0.03 0.050 19.00 • • • • 0.24-2.40 0.10-0.24 0.16-0.30

HGPL 4004Y 4.00 2.80 0.40 0.03 0.050 19.00 • • • • 0.48-2.40 0.10-0.24 0.16-0.30

HGPL 4020Y 4.00 2.80 2.00 0.03 0.050 19.00 • • • 0.00-2.00 0.10-0.24 0.16-0.30

HGPL 5005Y 5.00 3.30 0.50 0.03 0.050 19.00 • • • 0.60-3.00 0.12-0.24 0.20-0.38

HGPL 5025Y 5.00 3.30 2.50 0.03 0.050 19.00 • • • 0.00-2.50 0.12-0.24 0.20-0.38

HGPL 6005Y 6.00 4.20 0.50 0.03 0.050 19.00 • • • • 0.60-3.60 0.12-0.28 0.24-0.45

HGPL 6030Y 6.00 4.20 3.00 0.03 0.050 19.00 • • • 0.00-3.00 0.12-0.28 0.24-0.45

• No depth penetration limit • For cutting speed recommendations and user guide, see pages 604-613

(1) Cutting width tolerance (+/-)

(2) Corner radius tolerance (+/-)

For tools, see pages: C#-HFIR/L-MC (573) • HFAER/L-4 (565) • HFAER/L-5T, 6T (566) • HFAIR/L-4 (572) • HFAIR/L-DG (573) • HFFR/L-T (564)

• HFHR/L-4T (559) • HFHR/L-5T (560) • HFHR/L-6T (561) • HFIR/L-MC (574) • HFPAD-3 (562) • HFPAD-4 (563) • HFPAD-5 (563) • HFPAD-6 (564)

• HFPAD-JHP (562) • HGAER/L-3 (565) • HGAIR/L-3 (568) • HGHR/L-3 (558)

578 ISCAR