Page 67 - GARR_TOOL(CATALOG_INT)

P. 67

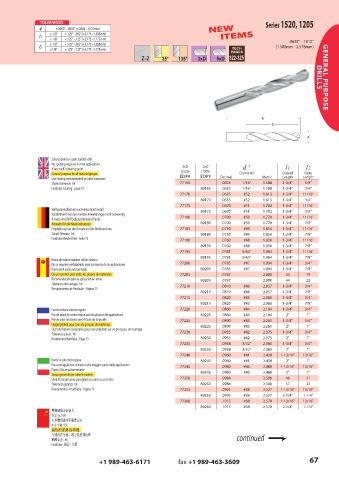

TOLERANCES Series 1520, 1205

NEW

d +.0000" –.0005" (+.0000 –.0127mm) NEW

ITEMS

≤ 1/8" +.125" –.062" (+3.175 –1.588mm) ITEMS

l1

> 1/8" +.125" –.125" (+3.175 –3.175mm) .0625" - .1015"

≤ 1/8" +.125" –.062" (+3.175 –1.588mm)

l2 (1.588mm - 2.578mm)

>1/8" +.125" –.125" (+3.175 –3.175mm)

3xD 5xD 322-325 DRILLS GENERAL PURPOSE

Solid submicron grain carbide drill

No spotting required in most applications 3xD 5xD d †

4-facet self-centering point l1 l2

(1520)

(1205)

General purpose for all material groups EDP# EDP# Diameter Overall Flute

Live tooling recommended on lathe processes Decimal Metric Length Length

Shank tolerance: h6 77165 .0625 1/16" 1.588 1-3/4" 5/8"

Hardlube Coating - page 73 89165 .0625 1/16" 1.588 1-3/4" 3/4"

77170 .0635 #52 1.613 1-3/4" 11/16"

89170 .0635 #52 1.613 1-3/4" 3/4"

77175 .0670 #51 1.702 1-3/4" 11/16"

Vollhartmetallbohrer aus Feinkornhartmetall 89175 .0670 #51 1.702 1-3/4" 3/4"

Vorzentrieren bei den meisten Anwendungen nicht notwendig

4-Fasen-Anschliff Selbstzentrierend Punkt 77180 .0700 #50 1.778 1-3/4" 11/16"

Allzweck für alle Materialgruppen 89180 .0700 #50 1.778 1-3/4" 7/8"

Empfehlung fuer den Einsatz auf der Drehmaschine 77185 .0730 #49 1.854 1-3/4" 11/16"

Schaft-Toleranz: h6 89185 .0730 #49 1.854 1-3/4" 7/8"

Hardlube-Beschichtet - Seite 73 77190 .0760 #48 1.930 1-3/4" 11/16"

89190 .0760 #48 1.930 1-3/4" 7/8"

77195 .0781 5/64" 1.984 1-3/4" 11/16"

89195 .0781 5/64" 1.984 1-3/4" 7/8"

Broca de submicrograno sólido carburo

No se requiere pretaladrado para la mayoría de las aplicaciones 77200 .0785 #47 1.994 1-3/4" 3/4"

Punta de 4 caras autocentrada 89200 .0785 #47 1.994 1-3/4" 7/8"

De uso general para todos los grupos de materiales 77205 .0787 2.000 44 19

Recomendación para la aplicación en torno 89205 .0787 2.000 44 22

Tolerancia del vástago: h6 77210 .0810 #46 2.057 1-3/4" 3/4"

Recubrimiento de Hardlube - Página 73

89210 .0810 #46 2.057 1-3/4" 7/8"

77215 .0820 #45 2.083 1-3/4" 3/4"

89215 .0820 #45 2.083 1-3/4" 7/8"

Forets carbure submicrograin 77220 .0860 #44 2.184 1-3/4" 3/4"

Pas de point de centre requis pour la plupart des applications 89220 .0860 #44 2.184 2" 1"

Pointe auto centrante avec 4 faces de depouille 77225 .0890 #43 2.261 1-3/4" 3/4"

Usage général pour tous les groupes de matériaux 89225 .0890 #43 2.261 2" 1"

Outil de filature nécessaires pour une utilisation sur un processus de tournage

Tolerance queue: h6 77230 .0935 #42 2.375 1-3/4" 3/4"

Revêtement Hardlube - Page 73 89230 .0935 #42 2.375 2" 1"

77235 .0938 3/32" 2.383 1-3/4" 3/4"

89235 .0938 3/32" 2.383 2" 1"

77240 .0960 #41 2.438 1-13/16" 13/16"

Punte in sub-micro grana 89240 .0960 #41 2.438 2" 1"

Pre-centraggio non richiesto nella maggior parte delle applicazioni 77245 .0980 #40 2.489 1-13/16" 13/16"

Punto 4 facce autocentrante

Scopo generale per tutte le materie 89245 .0980 #40 2.489 2" 1"

Utensili rotanti sono consigliate se usato su un tornio 77250 .0984 2.500 46 21

Tolleranza gambo: h6 89250 .0984 2.500 57 32

Rivestimento in Hardlube - Pagina 73 77255 .0995 #39 2.527 1-13/16" 13/16"

89255 .0995 #39 2.527 2-1/4" 1-1/4"

77260 .1015 #38 2.578 1-13/16" 13/16"

89260 .1015 #38 2.578 2-1/4" 1-1/4"

整体硬质合金钻头

自定心刀尖

在多数用途中不需要定心

4-小平面刀尖

通用使用的所有材料组

不建议在车床,或工具必须纺纱 continued ?

柄部公差: h6

Hardlube 涂层 - 73页

+1 989-463-6171 fax +1 989-463-3609 67