Page 205 - ISCAR(TURNING-CATALOG-42-2022)

P. 205

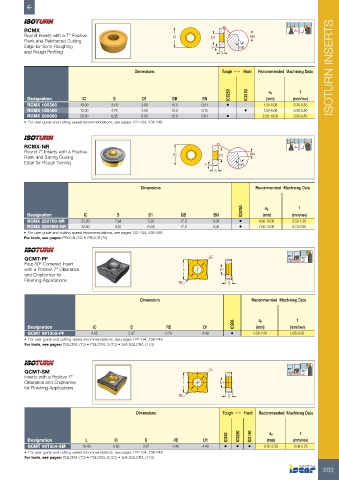

RCMX

Round Inserts with a 7° Positive IC D1 BN

Flank and Reinforced Cutting

Edge for Semi-Roughing 7° GB

and Rough Profiling S

Dimensions Tough 1 Hard Recommended Machining Data ISOTURN INSERTS

IC8250 IC8150 ap f

Designation IC S D1 GB BN (mm) (mm/rev)

RCMX 100300 10.00 3.18 3.60 15.0 0.01 • 1.50-5.00 0.30-0.50

RCMX 120400 12.00 4.76 4.20 15.0 0.15 • 1.50-6.00 0.30-0.50

RCMX 200600 20.00 6.35 6.50 15.0 0.01 • 2.50-10.00 0.50-0.50

• For user guide and cutting speed recommendations, see pages 122-134, 236-248

RCMX-NR

Round 7° Inserts with a Positive IC BN

Flank and Strong Cutting D1

Edge for Rough Turning

7° GB

S

Dimensions Recommended Machining Data

IC8250 ap f

Designation IC S D1 GB BN (mm) (mm/rev)

RCMX 250700-NR 25.00 7.94 7.20 17.0 0.30 • 4.00-10.00 0.50-1.50

RCMX 3209M0-NR 32.00 9.52 10.00 17.0 0.30 • 7.00-13.00 0.70-2.00

• For user guide and cutting speed recommendations, see pages 122-134, 236-248

For tools, see pages: PRDCN (72) • PRGCR (72)

QCMT-PF IC 95º 95°

Four 80° Cornered Insert

with a Positive 7° Clearance L D1

and Chipformer for

Finishing Applications

RE S

Dimensions Recommended Machining Data

IC908 ap f

Designation IC S RE D1 (mm) (mm/rev)

QCMT 09T302-PF 9.65 3.97 0.20 4.40 • 0.50-2.50 0.05-0.30

• For user guide and cutting speed recommendations, see pages 122-134, 236-248

For tools, see pages: PQLCR/L (73) • PQLCR/L-S (73) • S/A-SQLCR/L (110)

QCMT-SM IC 95º 95°

Inserts with a Positive 7°

Clearance and Chipformer L D1

for Finishing Applications

RE S

Dimensions Tough 1 Hard Recommended Machining Data

IC830 IC8250 IC8150 ap f

Designation L IC S RE D1 (mm) (mm/rev)

QCMT 09T304-SM 10.40 9.65 3.97 0.40 4.40 • • • 0.50-2.50 0.06-0.25

• For user guide and cutting speed recommendations, see pages 122-134, 236-248

For tools, see pages: PQLCR/L (73) • PQLCR/L-S (73) • S/A-SQLCR/L (110)

203