Page 210 - ISCAR(TURNING-CATALOG-42-2022)

P. 210

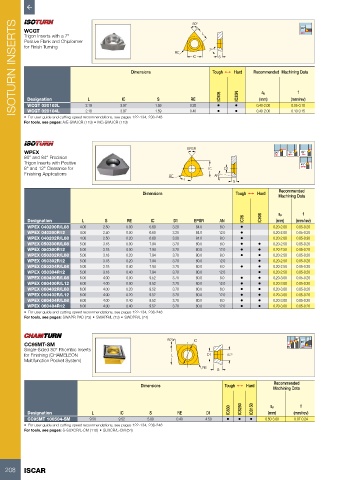

ISOTURN INSERTS WCGT Dimensions RE 80° L 7° Tough 1 Hard Recommended Machining Data

93º

Trigon Inserts with a 7°

Positive Flank and Chipformer

for Finish Turning

IC

S

f

ap

Designation

S

(mm)

IC

RE

L

2.18

1.59

WCGT 020102L

0.05-0.10

3.97

•

•

2.18

0.40

1.59

3.97

0.40-2.00

0.10-0.15

WCGT 020104L

• For user guide and cutting speed recommendations, see pages 122-134, 236-248 0.20 • IC908 • IC30N 0.40-2.00 (mm/rev)

For tools, see pages: A/E-SWUCR (119) • MG-SWUCR (119)

WPEX EPSR 90° 75° 60°

80° and 84° Precision

Trigon Inserts with Positive 45°

8° and 12° Clearance for IC D1

Finishing Applications RE AN°

L S

Recommended

Dimensions Tough 1 Hard

Machining Data

f

ap

Designation L S RE IC D1 EPSR AN IC08 IC908 (mm) (mm/rev)

WPEX 040200R/L08 4.00 2.50 0.00 6.60 3.20 84.0 8.0 • 0.20-2.00 0.05-0.20

WPEX 040200R12 4.00 2.50 0.00 6.60 3.20 84.0 12.0 • 0.20-2.00 0.05-0.20

WPEX 040202R/L08 4.00 2.50 0.20 6.60 3.20 84.0 8.0 • 0.20-2.00 0.05-0.20

WPEX 050300R/L08 5.00 3.18 0.00 7.94 3.70 80.0 8.0 • • 0.20-2.50 0.05-0.20

WPEX 050300R12 5.00 3.18 0.00 7.94 3.70 80.0 12.0 • • 0.20-2.50 0.05-0.20

WPEX 050302R/L08 5.00 3.18 0.20 7.94 3.70 80.0 8.0 • • 0.20-2.50 0.05-0.20

WPEX 050302R12 5.00 3.18 0.20 7.94 3.70 80.0 12.0 • 0.20-2.50 0.05-0.20

WPEX 050304R/L08 5.00 3.18 0.40 7.94 3.70 80.0 8.0 • • 0.20-2.50 0.05-0.20

WPEX 050304R12 5.00 3.18 0.40 7.94 3.70 80.0 12.0 • 0.20-2.50 0.05-0.20

WPEX 060400R/L08 6.00 4.00 0.00 9.52 3.70 80.0 8.0 • • 0.20-3.00 0.05-0.20

WPEX 060400R/L12 6.00 4.00 0.00 9.52 3.70 80.0 12.0 • • 0.20-3.00 0.05-0.20

WPEX 060402R/L08 6.00 4.00 0.20 9.52 3.70 80.0 8.0 • • 0.20-3.00 0.05-0.20

WPEX 060402R/L12 6.00 4.00 0.20 9.52 3.70 80.0 12.0 • • 0.20-3.00 0.05-0.20

WPEX 060404R/L08 6.00 4.00 0.40 9.52 3.70 80.0 8.0 • • 0.20-3.00 0.05-0.20

WPEX 060404R12 6.00 4.00 0.40 9.52 3.70 80.0 12.0 • • 0.20-3.00 0.05-0.20

• For user guide and cutting speed recommendations, see pages 122-134, 236-248

For tools, see pages: SWAPR-PAD (73) • SWAPR/L (73) • SWDPR/L (74)

95 º

CC95MT-SM 80° IC 95 º 95 º

Single-Sided 80° Rhombic Inserts

for Finishing (CHAMELEON L D1 6.2

Multifunction Pocket System)

RE S

Recommended

Dimensions Tough 1 Hard

Machining Data

f

ap

Designation L IC S RE D1 IC830 IC8250 IC8150 (mm) (mm/rev)

CC95MT 100504-SM 9.50 9.52 5.00 0.40 4.50 • • • 0.50-3.00 0.07-0.24

• For user guide and cutting speed recommendations, see pages 122-134, 236-248

For tools, see pages: S-SUXCR/L-CM (110) • SUXCR/L-CM (54)

208 ISCAR