Page 207 - ISCAR(TURNING-CATALOG-42-2022)

P. 207

60°

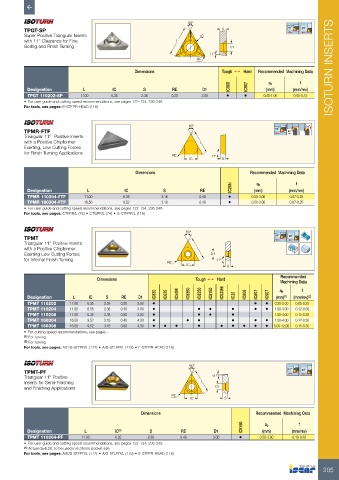

TPGT-SP S 91 º 95 º

Super Positive Triangular Inserts IC

with 11° Clearance for Fine L

Boring and Finish Turning D1

11˚

RE

Dimensions Tough 1 Hard Recommended Machining Data ISOTURN INSERTS

f

ap

Designation L IC S RE D1 IC908 IC907 (mm) (mm/rev)

TPGT 110202-SP 11.00 6.35 2.38 0.20 3.00 • • 0.40-1.00 0.05-0.15

• For user guide and cutting speed recommendations, see pages 122-134, 236-248

For tools, see pages: E-STFPR-HEAD (116)

60° 91 º

TPMR-FTF 91 º 91 º

Triangular 11° Positive Inserts

with a Positive Chipformer L

Exerting, Low Cutting Forces

for Finish Turning Applications

RE 11°

IC S

Dimensions Recommended Machining Data

IC20N ap f

Designation L IC S RE (mm) (mm/rev)

TPMR 110304-FTF 11.00 6.35 3.18 0.40 • 0.50-3.00 0.07-0.25

TPMR 160304-FTF 16.50 9.52 3.18 0.40 • 0.50-3.00 0.07-0.25

• For user guide and cutting speed recommendations, see pages 122-134, 236-248

For tools, see pages: CTFPR/L (75) • CTGPR/L (74) • S-CTFPR/L (116)

60°

TPMT 91 º 95 º

Triangular 11° Positive Inserts

with a Positive Chipformer L

Exerting Low Cutting Forces D1

for Internal Finish Turning 11°

RE

IC S

Recommended

Dimensions Tough 1 Hard

Machining Data

IC830 IC635 IC50M IC8350 IC8250 IC8150 IC520M IC806 IC807 IC907 ap f

Designation L IC S RE D1 IC20 (mm) (1) (mm/rev) (2)

TPMT 110202 11.00 6.35 2.38 0.20 3.00 • • • 0.20-2.00 0.05-0.25

TPMT 110204 11.00 6.35 2.38 0.40 3.00 • • • • • • 1.00-3.00 0.12-0.30

TPMT 110208 11.00 6.35 2.38 0.80 3.00 • • • • 1.00-4.00 0.15-0.30

TPMT 160304 16.50 9.52 3.18 0.40 4.30 • • • • • • 1.00-4.00 0.12-0.30

TPMT 160308 16.50 9.52 3.18 0.80 4.30 • • • • • • • • • 5.00-12.00 0.15-0.35

• For cutting speed recommendations, see pages ..

(1) For turning

(2) For turning

For tools, see pages: A/E/S-STFPR/L (117) • A/S-STLPR/L (118) • E-STFPR-HEAD (116)

60°

TPMT-PF 91 º 95 º

Triangular 11° Positive 11°

Inserts for Semi-Finishing L

and Finishing Applications D1

RE

IC S

Dimensions Recommended Machining Data

IC8150 ap f

Designation L IC (1) S RE D1 (mm) (mm/rev)

TPMT 110204-PF 11.00 6.35 2.38 0.40 3.00 • 0.50-3.00 0.10-0.30

• For user guide and cutting speed recommendations, see pages 122-134, 236-248

(1) Actual di=6.28, to be used in 6.35mm pocket size

For tools, see pages: A/E/S-STFPR/L (117) • A/S-STLPR/L (118) • E-STFPR-HEAD (116)

205