Page 272 - ISCAR(TURNING-CATALOG-42-2022)

P. 272

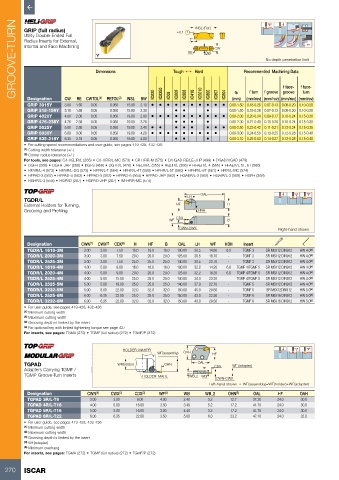

GROOVE-TURN GRIP (full radius) Dimensions Tough 1 Hard BW CW Recommended Machining Data

INSL (Ref.)

±0.1

Utility Double-Ended Full

7°

Radius Inserts for External,

Internal and Face Machining

RE

No depth penetration limit

f face-

f face-

groove

f turn

f groove

turn

ap

(mm/rev) (mm/rev) (mm/rev) (mm/rev)

(mm)

RE

2.10 • • • • • • • • • •

15.80

0.05

3.00

0.050

GRIP 3015Y

Designation CW 1.50 CWTOL (1) RETOL (2) INSL BW IC830 IC8250 IC08 IC808 IC908 IC418 IC5010 IC806 IC807 IC804 0.00-1.50 0.18-0.26 0.07-0.13 0.08-0.20 0.10-0.20

GRIP 318-159Y 3.18 1.59 0.05 0.050 15.80 2.30 • • • 0.00-1.50 0.19-0.28 0.07-0.13 0.08-0.20 0.10-0.20

GRIP 4020Y 4.00 2.00 0.05 0.050 19.00 2.80 • • • • • • • • • • 0.00-2.00 0.20-0.34 0.09-0.17 0.10-0.24 0.15-0.30

GRIP 476-238Y 4.76 2.38 0.05 0.050 19.00 3.20 • • • • 0.00-2.30 0.21-0.40 0.10-0.20 0.10-0.24 0.15-0.30

GRIP 5025Y 5.00 2.50 0.05 0.050 19.00 3.40 • • • • • • • • 0.00-2.50 0.23-0.42 0.11-0.21 0.12-0.24 0.15-0.35

GRIP 6030Y 6.00 3.00 0.05 0.050 19.00 4.20 • • • • • • • • • 0.00-3.00 0.24-0.50 0.13-0.25 0.12-0.28 0.15-0.40

GRIP 635-318Y 6.35 3.18 0.05 0.050 19.00 4.00 • • • 0.00-3.10 0.25-0.53 0.14-0.27 0.12-0.28 0.15-0.40

• For cutting speed recommendations and user guide, see pages 419-428, 432-436

(1) Cutting width tolerance (+/-)

(2) Corner radius tolerance (+/-)

For tools, see pages: C#-HELIR/L (265) • C#-HFIR/L-MC (573) • CR HFIR-M (575) • D/HGAD RE/LE-JHP (499) • DGAD/HGAD (479)

• DGFH (268) • DGFH-JHP (269) • DGFS (469) • DGTR/L (476) • HELIIR/L (355) • HELIR/L (266) • HFAER/L-4 (565) • HFAER/L-5T, 6T (566)

• HFAIR/L-4 (572) • HFAIR/L-DG (573) • HFFR/L-T (564) • HFHR/L-4T (559) • HFHR/L-5T (560) • HFHR/L-6T (561) • HFIR/L-MC (574)

• HFPAD-3 (562) • HFPAD-4 (563) • HFPAD-5 (563) • HFPAD-6 (564) • HFPAD-JHP (562) • HGAER/L-3 (565) • HGAIR/L-3 (568) • HGFH (268)

• HGHR/L-3 (558) • HGPAD (267) • HGPAD-JHP (267) • IM-HFIR-MC (574)

OAL

TGDR/L LH

External Holders for Turning, HF H

Grooving and Profiling HBH

CDX

WF B

CWN-CWX Right-hand shown

Designation CWN (1) CWX (2) CDX (3) H HF B OAL LH WF HBH Insert

TGDR/L 1616-3M 3.00 3.00 7.50 16.0 16.0 16.0 100.00 30.5 14.80 6.0 TGMF 3 SR M5X12 DIN912 HW 4.0 (a)

TGDR/L 2020-3M 3.00 3.00 7.50 20.0 20.0 20.0 125.00 30.5 18.70 - TGMF 3 SR M5X12 DIN912 HW 4.0 (a)

TGDR/L 2525-3M 3.00 3.00 7.50 25.0 25.0 25.0 140.00 30.5 23.70 - TGMF 3 SR M5X12 DIN912 HW 4.0 (a)

TGDR/L 1616-4M 4.00 5.00 9.00 16.0 16.0 16.0 100.00 32.2 14.20 6.0 TGMF 4/TGMF 5 SR M5X12 DIN912 HW 4.0 (a)

TGDR/L 2020-4M 4.00 5.00 9.00 20.0 20.0 20.0 125.00 32.2 18.20 6.0 TGMF 4/TGMF 5 SR M5X12 DIN912 HW 4.0 (a)

TGDR/L 2525-4M 4.00 5.00 15.50 25.0 25.0 25.0 140.00 34.0 23.20 - TGMF 4/TGMF 5 SR M5X12 DIN912 HW 4.0 (a)

TGDR/L 2525-5M 5.00 5.00 18.00 25.0 25.0 25.0 140.00 37.0 22.70 - TGMF 5 SR M5X12 DIN912 HW 4.0 (a)

TGDR/L 3232-5M 5.00 5.00 22.00 32.0 32.0 32.0 150.00 45.0 29.80 - TGMF 5 SR M6X12DIN912 HW 5.0 (a)

TGDR/L 2525-6M 6.00 6.35 22.00 25.0 25.0 25.0 150.00 43.0 22.50 - TGMF 6 SR M6X16 DIN912 HW 5.0 (a)

TGDR/L 3232-6M 6.00 6.35 22.00 32.0 32.0 32.0 150.00 43.0 29.50 - TGMF 6 SR M6X16 DIN912 HW 5.0 (a)

• For user guide, see pages 419-428, 432-436

(1) Minimum cutting width

(2) Maximum cutting width

(3) Grooving depth is limited by the insert

(a) For optional key with limited tightening torque see page 427

For inserts, see pages: TGMA (272) • TGMF (full radius) (272) • TGMF/P (272)

HOLDER: MAHPR

WF(assembly) OAH HF

TGPAD WF(holder) OHN OAL CDX WF (adapter)

Adapters Carrying TGMF /

TGMP Groove-Turn Inserts HOLDER: MAHL WB_2 WB

CWN-CWX

Left-hand shown • WF(assembly)=WF(holder)+WF(adapter)

Designation CWN (1) CWX (2) CDX (3) WF (4) WB WB_2 OHN (5) OAL HF OAH

TGPAD 3R/L-T9 3.00 3.00 9.00 4.00 2.40 5.2 12.7 37.20 24.0 30.0

TGPAD 4R/L-T16 4.00 5.00 16.00 3.50 3.40 5.2 17.2 41.70 24.0 30.0

TGPAD 5R/L-T16 5.00 5.00 16.00 3.00 4.40 5.2 17.2 41.70 24.0 30.0

TGPAD 6R/L-T22 6.00 6.35 22.00 3.50 5.00 6.0 23.2 47.10 24.0 32.0

• For user guide, see pages 419-428, 432-436

(1) Minimum cutting width

(2) Maximum cutting width

(3) Grooving depth is limited by the insert

(4) WF(adapter)

(5) Minimum overhang

For inserts, see pages: TGMA (272) • TGMF (full radius) (272) • TGMF/P (272)

270 ISCAR