Page 273 - ISCAR(TURNING-CATALOG-42-2022)

P. 273

OAL

OAH

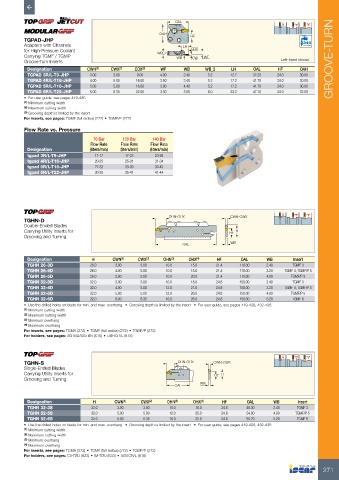

TGPAD-JHP HF

Adapters with Channels LH Bar Max

for High-Pressure Coolant WB_2 CDX

Carrying TGMF / TGMP WB CW WF

Groove-Turn Inserts Left-hand shown GROOVE-TURN

Designation CWN (1) CWX (2) CDX (3) WF WB WB_2 LH OAL HF OAH

TGPAD 3R/L-T9-JHP 3.00 3.00 9.00 4.00 2.40 5.2 12.7 37.20 24.0 30.00

TGPAD 4R/L-T16-JHP 4.00 5.00 16.00 3.50 3.40 5.2 17.2 41.70 24.0 30.00

TGPAD 5R/L-T16-JHP 5.00 5.00 16.00 3.00 4.40 5.2 17.2 41.70 24.0 30.00

TGPAD 6R/L-T22-JHP 6.00 6.35 22.00 3.50 5.00 6.0 23.2 47.10 24.0 32.00

• For user guide, see pages 419-436

(1) Minimum cutting width

(2) Maximum cutting width

(3) Grooving depth is limited by the insert

For inserts, see pages: TGMF (full radius) (272) • TGMF/P (272)

Flow Rate vs. Pressure

70 Bar 100 Bar 140 Bar

Flow Rate Flow Rate Flow Rate

Designation (liters/min) (liters/min) (liters/min)

tgpad 3R/L-T9-JHP 11-17 17-23 23-26

tgpad 4R/L-T16-JHP 20-25 25-31 31-34

tgpad 5R/L-T16-JHP 27-33 33-39 39-43

tgpad 6R/L-T22-JHP 30-35 35-41 41-44

TGHN-D OHN-OHX CWN-CWX

Double-Ended Blades

Carrying Utility Inserts for HF H

Grooving and Turning

OAL WB

Designation H CWN (1) CWX (2) OHN (3) OHX (4) HF OAL WB Insert

TGHN 26-3D 26.0 3.00 3.00 10.0 15.0 21.4 110.00 2.40 TGMF 3

TGHN 26-4D 26.0 4.00 5.00 10.0 15.0 21.4 110.00 3.20 TGMF 4, TGMF/P 5

TGHN 26-5D 26.0 5.00 5.00 10.0 20.0 21.4 110.00 4.00 TGMF/P 5

TGHN 32-3D 32.0 3.00 3.00 10.0 18.0 24.8 150.00 2.40 TGMF 3

TGHN 32-4D 32.0 4.00 5.00 12.0 21.0 24.8 150.00 3.20 TGMF 4, TGMF/P 5

TGHN 32-5D 32.0 5.00 5.00 12.0 26.0 24.8 150.00 4.00 TGMF/P 5

TGHN 32-6D 32.0 6.00 6.35 16.0 26.0 24.8 150.00 5.20 TGMF 6

• Use the drilled holes on blade for min. and max. overhang • Grooving depth is limited by the insert • For user guide, see pages 419-428, 432-436

(1) Minimum cutting width

(2) Maximum cutting width

(3) Minimum overhang

(4) Maximum overhang

For inserts, see pages: TGMA (272) • TGMF (full radius) (272) • TGMF/P (272)

For holders, see pages: SGTBU/SGTBN (616) • UBHCR/L (618)

TGHN-S OHN-OHX CWN-CWX

Single-Ended Blades

Carrying Utility Inserts for HF H

Grooving and Turning

WB

OAL

Designation H CWN (1) CWX (2) OHN (3) OHX (4) HF OAL WB Insert

TGHN 32-3S 32.0 3.00 3.00 10.0 18.0 24.8 48.30 2.40 TGMF 3

TGHN 32-5S 32.0 5.00 5.00 12.0 25.0 24.8 54.00 4.00 TGMF/P 5

TGHN 32-6S 32.0 6.00 6.35 16.0 25.0 24.8 55.70 5.20 TGMF 6

• Use the drilled holes on blade for min. and max. overhang • Grooving depth is limited by the insert • For user guide, see pages 419-428, 432-436

(1) Minimum cutting width

(2) Maximum cutting width

(3) Minimum overhang

(4) Maximum overhang

For inserts, see pages: TGMA (272) • TGMF (full radius) (272) • TGMF/P (272)

For holders, see pages: C#-TBU (623) • IM-TBU (633) • UBHCR/L (618)

271