Page 299 - ISCAR(TURNING-CATALOG-42-2022)

P. 299

±0.025

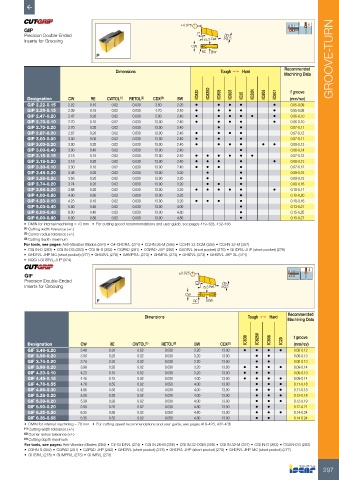

GIP

Precision Double-Ended 7° 5

Inserts for Grooving 15.3 Ref.

CW

RE BW GROOVE-TURN

Dimensions Tough 1 Hard Recommended

Machining Data

IC830 IC8250 IC808 IC908 IC20 IC20N IC806 IC807 f groove

Designation CW RE CWTOL (1) RETOL (2) CDX (3) BW (mm/rev)

GIP 2.22-0.15 2.22 0.15 0.02 0.030 3.50 2.20 • • • • • 0.05-0.09

GIP 2.39-0.15 2.39 0.15 0.02 0.030 4.70 2.40 • • • • • 0.05-0.09

GIP 2.47-0.20 2.47 0.20 0.02 0.030 5.00 2.40 • • • • • • 0.06-0.10

GIP 2.70-0.10 2.70 0.10 0.02 0.030 13.00 2.40 • • • • • 0.06-0.10

GIP 2.70-0.20 2.70 0.20 0.02 0.030 13.00 2.40 • • 0.07-0.11

GIP 2.87-0.20 2.87 0.20 0.02 0.030 13.00 2.40 • • • • 0.07-0.12

GIP 3.00-0.00 3.00 0.00 0.02 0.030 13.00 2.40 • • • 0.07-0.11

GIP 3.00-0.20 3.00 0.20 0.02 0.030 13.00 2.40 • • • • • • 0.08-0.13

GIP 3.00-0.40 3.00 0.40 0.02 0.030 13.00 2.40 • 0.08-0.14

GIP 3.15-0.15 3.15 0.15 0.02 0.030 13.00 2.40 • • • • • • 0.07-0.12

GIP 3.18-0.20 3.18 0.20 0.02 0.030 13.00 2.40 • • • • • 0.08-0.13

GIP 3.30-0.10 3.30 0.10 0.02 0.030 13.00 2.40 • • • • 0.07-0.12

GIP 3.48-0.20 3.48 0.20 0.02 0.030 13.00 3.20 • • 0.09-0.15

GIP 3.56-0.20 3.56 0.20 0.02 0.030 13.00 3.20 • • 0.09-0.15

GIP 3.74-0.20 3.74 0.20 0.02 0.030 13.00 3.20 • • • 0.09-0.16

GIP 3.98-0.20 3.98 0.20 0.02 0.030 13.00 3.20 • • • • • • 0.10-0.17

GIP 4.00-0.80 4.00 0.80 0.02 0.050 13.00 3.20 • 0.10-0.20

GIP 4.23-0.10 4.23 0.10 0.02 0.030 13.00 3.20 • • • • 0.10-0.16

GIP 5.00-0.40 5.00 0.40 0.02 0.030 13.00 4.00 • 0.13-0.21

GIP 6.00-0.40 6.00 0.40 0.02 0.030 13.00 4.80 • 0.15-0.25

GIP 6.00-0.80 6.00 0.80 0.02 0.050 13.00 4.80 • 0.15-0.27

• DMIN for internal machining = 70 mm • For cutting speed recommendations and user guide, see pages 419-428, 432-436

(1) Cutting width tolerance (+/-)

(2) Corner radius tolerance (+/-)

(3) Cutting depth maximum

For tools, see pages: Anti-Vibration Blades (284) • C#-GHDR/L (274) • CGHN 26-M (356) • CGHN 32-DGM (358) • CGHN 32-M (357)

• CGHN-D (283) • CGHN-DG (283) • CGHN-S (282) • CGPAD (281) • CGPAD-JHP (282) • GHDR/L (short pocket) (275) • GHDR/L-JHP (short pocket) (276)

• GHDR/L-JHP-MC (short pocket) (277) • GHGR/L (278) • GHMPR/L (273) • GHMR/L (273) • GHSR/L (373) • GHSR/L-JHP-SL (374)

• NQCH-GHSR/L-JHP (374)

GIF ±0.025

Precision Double-Ended 7°

Inserts for Grooving 15.3 Ref. 5

CW

RE BW

Recommended

Dimensions Tough 1 Hard

Machining Data

IC830 IC8250 IC808 IC20 f groove

Designation CW RE CWTOL (1) RETOL (2) BW CDX (3) (mm/rev)

GIF 3.48-0.20 3.48 0.20 0.02 0.030 3.20 13.00 • • • • 0.08-0.12

GIF 3.56-0.20 3.56 0.20 0.02 0.030 3.20 13.00 • • 0.08-0.13

GIF 3.74-0.20 3.74 0.20 0.02 0.030 3.20 13.00 • • 0.08-0.13

GIF 3.98-0.20 3.98 0.20 0.02 0.030 3.20 13.00 • • • • 0.09-0.14

GIF 4.23-0.10 4.23 0.10 0.02 0.030 3.20 13.00 • • • 0.08-0.13

GIF 4.45-0.15 4.45 0.15 0.02 0.030 4.00 13.00 • • • • 0.09-0.14

GIF 4.78-0.55 4.78 0.55 0.02 0.050 4.00 13.00 • • • 0.11-0.18

GIF 4.86-0.30 4.86 0.30 0.02 0.030 4.00 13.00 • • • 0.11-0.18

GIF 5.28-0.20 5.28 0.20 0.02 0.030 4.00 13.00 • • • 0.12-0.18

GIF 5.39-0.20 5.39 0.20 0.02 0.030 4.00 13.00 • • • 0.12-0.19

GIF 5.90-0.20 5.90 0.20 0.02 0.030 4.80 13.00 • • 0.12-0.21

GIF 6.35-0.50 6.35 0.50 0.02 0.050 4.80 13.00 • • • 0.14-0.24

GIF 6.35-0.55 6.35 0.55 0.02 0.050 4.80 13.00 • • 0.14-0.24

• DMIN for internal machining = 70 mm • For cutting speed recommendations and user guide, see pages 419-428, 432-436

(1) Cutting width tolerance (+/-)

(2) Corner radius tolerance (+/-)

(3) Cutting depth maximum

For tools, see pages: Anti-Vibration Blades (284) • C#-GHDR/L (274) • CGHN 26-M (356) • CGHN 32-DGM (358) • CGHN 32-M (357) • CGHN-D (283) • CGHN-DG (283)

• CGHN-S (282) • CGPAD (281) • CGPAD-JHP (282) • GHDR/L (short pocket) (275) • GHDR/L-JHP (short pocket) (276) • GHDR/L-JHP-MC (short pocket) (277)

• GHGR/L (278) • GHMPR/L (273) • GHMR/L (273)

297