Page 483 - ISCAR(TURNING-CATALOG-42-2022)

P. 483

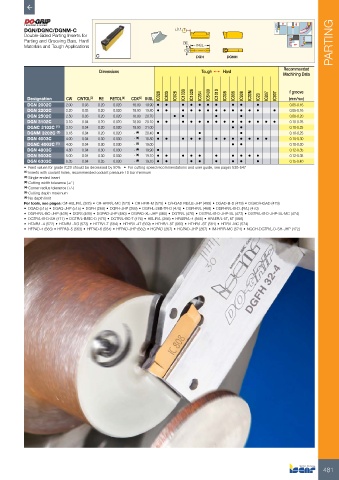

DGN/DGNC/DGNM-C ±0.1

Double-Sided Parting Inserts for

Parting and Grooving Bars, Hard RE PARTING

Materials and Tough Applications INSL

CW

DGN DGNM

Dimensions Tough 1 Hard Recommended

Machining Data

IC328 IC830 IC928 IC1030 IC1028 IC354 IC5400 IC1010 IC308 IC808 IC908 IC30N IC807 IC907 f groove

Designation CW CWTOL (3) RE RETOL (4) CDX (5) INSL IC20 (mm/rev)

DGN 2002C 2.00 0.03 0.20 0.020 18.00 19.90 • • • • • • • • • • 0.05-0.16

DGN 2202C 2.20 0.03 0.20 0.020 18.00 19.80 • • • • • • • • • • • • • 0.05-0.16

DGN 2502C 2.50 0.03 0.20 0.020 18.00 20.70 • • • • 0.08-0.20

DGN 3102C 3.10 0.04 0.20 0.020 18.00 20.10 • • • • • • • • • • • • • • 0.10-0.25

DGNC 3102C (1) 3.10 0.04 0.20 0.020 18.00 21.00 • • 0.10-0.25

DGNM 3202C (2) 3.18 0.04 0.20 0.020 - (6) 20.40 • • • 0.10-0.25

DGN 4003C 4.00 0.04 0.30 0.030 - 18.80 • • • • • • • • • • • • 0.10-0.30

(6)

DGNC 4003C (1) 4.00 0.04 0.30 0.030 - 19.00 • • 0.10-0.30

(6)

DGN 4803C 4.80 0.04 0.30 0.030 - 19.90 • 0.12-0.35

(6)

DGN 5003C 5.00 0.04 0.30 0.030 - 19.10 • • • • • • • • • • 0.12-0.35

(6)

DGN 6303C 6.35 0.04 0.35 0.030 - 19.10 • • • • • • • • 0.15-0.40

(6)

• Feed values for grade IC20 should be decreased by 50% • For cutting speed recommendations and user guide, see pages 538-547

(1) Inserts with coolant holes, recommended coolant pressure 10 bar minimum

(2) Single-ended insert

(3) Cutting width tolerance (+/-)

(4) Corner radius tolerance (+/-)

(5) Cutting depth maximum

(6) No depth limit

For tools, see pages: C#-HELIR/L (265) • C#-HFIR/L-MC (573) • CR HFIR-M (575) • D/HGAD RE/LE-JHP (499) • DGAD-B-D (479) • DGAD/HGAD (479)

• DGAQ (515) • DGAQ-JHP (515) • DGFH (268) • DGFH-JHP (269) • DGFHL-26B-TR-D (470) • DGFHR/L (468) • DGFHR/L-B-D..(R/L) (470)

• DGFHR/L-BC-JHP (469) • DGFS (469) • DGPAD-JHP (480) • DGPAD-XL-JHP (480) • DGTR/L (476) • DGTR/L-B-D-JHP-SL (473) • DGTR/L-B-D-JHP-SL-MC (474)

• DGTR/L-B-D-SH (471) • DGTR/L-B/BC-D (475) • DGTR/L-BC-T (476) • HELIR/L (266) • HFAER/L-4 (565) • HFAER/L-5T, 6T (566)

• HFAIR/L-4 (572) • HFAIR/L-DG (573) • HFFR/L-T (564) • HFHR/L-4T (559) • HFHR/L-5T (560) • HFHR/L-6T (561) • HFIR/L-MC (574)

• HFPAD-4 (563) • HFPAD-5 (563) • HFPAD-6 (564) • HFPAD-JHP (562) • HGPAD (267) • HGPAD-JHP (267) • IM-HFIR-MC (574) • NQCH-DGTR/L-D-SH-JHP (472)

481