Page 509 - ISCAR(TURNING-CATALOG-42-2022)

P. 509

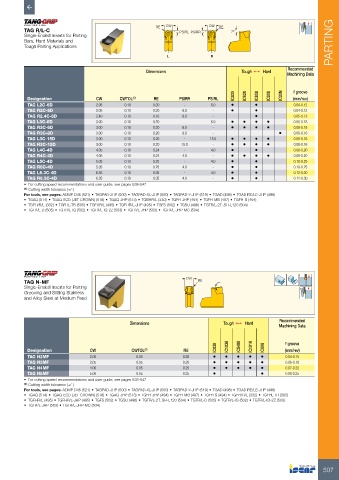

TAG R/L-C RE CW CW RE 7º

Single-Ended Inserts for Parting PSIRL PSIRR

Bars, Hard Materials and PARTING

Tough Parting Applications

L R

Dimensions Tough 1 Hard Recommended

Machining Data

IC830 IC928 IC808 IC908 IC30N f groove

Designation CW CWTOL (1) RE PSIRR PSIRL (mm/rev)

TAG L2C-6D 2.05 0.10 0.20 - 6.0 • • 0.04-0.12

TAG R2C-6D 2.05 0.10 0.20 6.0 - • • 0.04-0.12

TAG R2.4C-8D 2.40 0.10 0.16 8.0 - • 0.05-0.13

TAG L3C-6D 3.00 0.10 0.20 - 6.0 • • • • 0.08-0.18

TAG R3C-6D 3.00 0.10 0.20 6.0 - • • • • 0.08-0.18

TAG R3C-8D 3.00 0.10 0.20 8.0 - • 0.06-0.16

TAG L3C-15D 3.00 0.10 0.20 - 15.0 • • • • 0.08-0.16

TAG R3C-15D 3.00 0.10 0.20 15.0 - • • • • 0.08-0.16

TAG L4C-4D 4.05 0.10 0.24 - 4.0 • • 0.08-0.20

TAG R4C-4D 4.05 0.10 0.24 4.0 - • • • • 0.08-0.20

TAG L5C-4D 5.05 0.10 0.25 - 4.0 • • 0.10-0.25

TAG R5C-4D 5.05 0.10 0.25 4.0 - • • 0.10-0.25

TAG L6.3C-4D 6.35 0.10 0.35 - 4.0 • • 0.12-0.30

TAG R6.3C-4D 6.35 0.10 0.35 4.0 - • • 0.12-0.30

• For cutting speed recommendations and user guide, see pages 538-547

(1) Cutting width tolerance (+/-)

For tools, see pages: ADMP D45 (521) • TAGPAD-JHP (500) • TAGPAD-XL-JHP (500) • TAGPAD-Y-JHP (519) • TGAD (498) • TGAD RE/LE-JHP (498)

• TGAQ (514) • TGAQ-ECD (JET-CROWN) (516) • TGAQ-JHP (513) • TGBHR/L (330) • TGFH-JHP (494) • TGFH-MB (497) • TGFH-S (494)

• TGFH/R/L (332) • TGFHL-TR (505) • TGFHR/L (495) • TGFHR/L-JHP (495) • TGFS (502) • TGSU (496) • TGTR/L-2T..SH-L120 (504)

• TGTR/L-D (505) • TGTR/L-IQ (502) • TGTR/L-IQ-2Z (503) • TGTR/L-JHP (503) • TGTR/L-JHP-MC (504)

TAG N-MF CW RE 7°

Single-Ended Inserts for Parting

Grooving and Slitting Stainless

and Alloy Steel at Medium Feed

Recommended

Dimensions Tough 1 Hard Machining Data

IC830 IC1030 IC5400 IC1010 IC808 f groove

Designation CW CWTOL (1) RE (mm/rev)

TAG N2MF 2.00 0.05 0.20 • • • • • 0.04-0.15

TAG N3MF 3.05 0.05 0.20 • • • • • 0.06-0.18

TAG N4MF 4.00 0.05 0.25 • • • • • 0.07-0.22

TAG N5MF 5.00 0.05 0.25 • • 0.08-0.25

• For cutting speed recommendations and user guide, see pages 538-547

(1) Cutting width tolerance (+/-)

For tools, see pages: ADMP D45 (521) • TAGPAD-JHP (500) • TAGPAD-XL-JHP (500) • TAGPAD-Y-JHP (519) • TGAD (498) • TGAD RE/LE-JHP (498)

• TGAQ (514) • TGAQ-ECD (JET-CROWN) (516) • TGAQ-JHP (513) • TGFH-JHP (494) • TGFH-MB (497) • TGFH-S (494) • TGFH/R/L (332) • TGFHL-TR (505)

• TGFHR/L (495) • TGFHR/L-JHP (495) • TGFS (502) • TGSU (496) • TGTR/L-2T..SH-L120 (504) • TGTR/L-D (505) • TGTR/L-IQ (502) • TGTR/L-IQ-2Z (503)

• TGTR/L-JHP (503) • TGTR/L-JHP-MC (504)

507