Page 57 - GARR_TOOL(CATALOG_INT)

P. 57

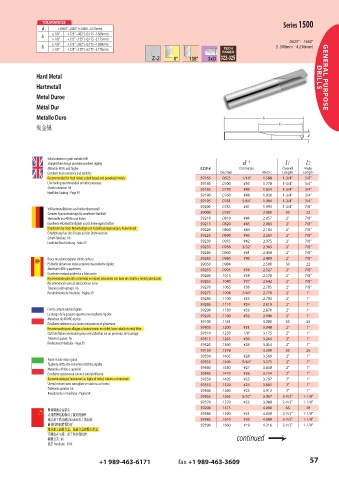

TOLERANCES Series 1500

d +.0000" –.0005" (+.0000 –.0127mm)

≤ 1/8" +.125" –.062" (+3.175 –1.588mm)

l1

> 1/8" +.125" –.125" (+3.175 –3.175mm) .0625" - .1660"

≤ 1/8" +.125" –.062" (+3.175 –1.588mm)

l2 (1.588mm - 4.216mm)

>1/8" +.125" –.125" (+3.175 –3.175mm)

0° 3xD 322-325

Hard Metal DRILLS GENERAL PURPOSE

Hartmetall

Metal Duroe

Métal Dur

Metallo Duro

硬金属

硬金属

Solid submicron grain carbide drill

Straight flute design provides excellent rigidity d † l1 l2

Materials 40 Rc and higher EDP# Diameter Overall Flute

Excellent heat resistance and lubricity Decimal Metric Length Length

Recommended for high nickel, cobalt based and powdered metals 59165 .0625 1/16" 1.588 1-3/4" 5/8"

Live tooling recommended on lathe processes 59180 .0700 #50 1.778 1-3/4" 3/4"

Shank tolerance: h6 59185 .0730 #49 1.854 1-3/4" 3/4"

Hardlube Coating - Page 59

59190 .0760 #48 1.930 1-3/4" 3/4"

59195 .0781 5/64" 1.984 1-3/4" 3/4"

59200 .0785 #47 1.994 1-3/4" 7/8"

Vollhartmetallbohrer aus Feinkornhartmetall

Gerades Spannutendesign für exzellente Stabilität 39000 .0787 2.000 50 22

Werkstoffe mit 40HRc und höher 59210 .0810 #46 2.057 2" 7/8"

Exzellente Hitzebeständigkeit und Schmiereigenschaften 59215 .0820 #45 2.083 2" 7/8"

Empfohlen für Hoch Nickelhaltige und Kobaltbasislegierungen, Pulvermetall 59220 .0860 #44 2.184 2" 7/8"

Empfehlung fuer den Einsatz auf der Drehmaschine 59225 .0890 #43 2.261 2" 7/8"

Schaft-Toleranz: h6

Hardlube Beschichtung - Seite 59 59230 .0935 #42 2.375 2" 7/8"

59235 .0938 3/32" 2.383 2" 7/8"

59240 .0960 #41 2.438 2" 7/8"

Broca de submicrograno sólido carburo 59245 .0980 #40 2.489 2" 7/8"

El diseño de ranuras rectas proporciona excelente rigidez 39050 .0984 2.500 50 22

Materiales 40Rc y superiores 59255 .0995 #39 2.527 2" 7/8"

Excelente resistencia térmica y lubricación 59260 .1015 #38 2.578 2" 7/8"

Recomendado para alto contenido en níquel, aleaciones con base de cobalto y metal pulverizado

Recomendación para la aplicación en torno 59265 .1040 #37 2.642 2" 7/8"

Tolerancia del vástago: h6 59270 .1065 #36 2.705 2" 7/8"

Recubrimiento de Hardlube - Página 59 59275 .1094 7/64" 2.779 2" 1"

59280 .1100 #35 2.794 2" 1"

59285 .1110 #34 2.819 2" 1"

Forets carbure submicrograin 59290 .1130 #33 2.870 2" 1"

Le design de la goujure apporte une excellente rigidite 59295 .1160 #32 2.946 2" 1"

Materiaux de 40 HRC et plus

Excellente resistance a la haute temperature et glissement 39100 .1181 3.000 50 25

Recommander pour alliages a hautes teneur en nickel, base cobalt et metal fritte 59305 .1200 #31 3.048 2" 1"

Outil de filature nécessaires pour une utilisation sur un processus de tournage 59310 .1250 1/8" 3.175 2" 1"

Tolerance queue: h6 59315 .1285 #30 3.264 2" 1"

Revêtement Hardlube - Page 59 59320 .1360 #29 3.454 2" 1"

39150 .1378 3.500 50 25

59330 .1405 #28 3.569 2" 1"

Punte in sub-micro grana

Tagliente dritto che consente un’ottima rigidità 59335 .1406 9/64" 3.571 2" 1"

Materiali a 40 Hrc e superiori 59340 .1440 #27 3.658 2" 1"

Eccellente resistenza al calore e autolubrificante 59345 .1470 #26 3.734 2" 1"

Raccomandata per lavorazioni su leghe di nickel, cobalto e sinterizzati 59350 .1495 #25 3.797 2" 1"

Utensili rotanti sono consigliate se usato su un tornio 59355 .1520 #24 3.861 2" 1"

Tolleranza gambo: h6 59360 .1540 #23 3.912 2" 1"

Rivestimento in Hardlube - Pagina 59

59365 .1562 5/32" 3.967 2-1/2" 1-1/8"

59370 .1570 #22 3.988 2-1/2" 1-1/8"

39200 .1575 4.000 63 28

整体硬质合金钻头

直排屑槽结构保证了极好的刚性 59380 .1590 #21 4.039 2-1/2" 1-1/8"

推荐加工洛氏硬度40或40以上的材质 59385 .1610 #20 4.089 2-1/2" 1-1/8"

耐热性和润滑性特好 59390 .1660 #19 4.216 2-1/2" 1-1/8"

推荐加工高镍合金、钴基合金和粉末冶金

不建议在车床,或工具必须纺纱

柄部公差: h6 continued ?

涂层 Hardlube - 59页

+1 989-463-6171 fax +1 989-463-3609 57