Page 152 - ISCAR(MILLINGCATALOG 38_2021)

P. 152

Rd°

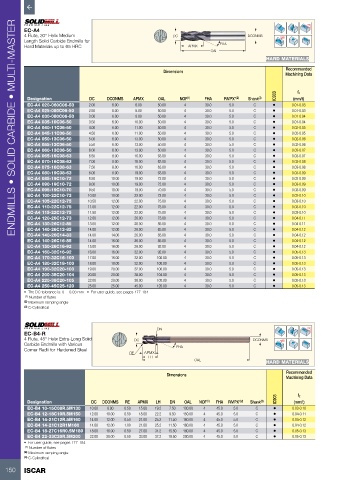

ENDMILLS • SOLID CARBIDE • MULTI-MASTER

EC-A4

4 Flute, 30° Helix Medium DC DCONMS

Length Solid Carbide Endmills for

Hard Materials up to 65 HRC APMX FHA

OAL

HARD MATERIALS

Dimensions Recommended

Machining Data

IC903 fz

Designation DC DCONMS APMX OAL NOF (1) FHA RMPX° (2) Shank (3) (mm/t)

EC-A4 020-060C06-50 2.00 6.00 6.00 50.00 4 30.0 5.0 C • 0.01-0.03

EC-A4 025-080C06-50 2.50 6.00 8.00 50.00 4 30.0 5.0 C • 0.01-0.03

EC-A4 030-080C06-50 3.00 6.00 8.00 50.00 4 30.0 5.0 C • 0.01-0.04

EC-A4 035-10C06-50 3.50 6.00 10.00 50.00 4 30.0 5.0 C • 0.01-0.04

EC-A4 040-11C06-50 4.00 6.00 11.00 50.00 4 30.0 5.0 C • 0.02-0.05

EC-A4 045-11C06-50 4.50 6.00 11.00 50.00 4 30.0 5.0 C • 0.02-0.05

EC-A4 050-13C06-50 5.00 6.00 13.00 50.00 4 30.0 5.0 C • 0.02-0.06

EC-A4 055-13C06-50 5.50 6.00 13.00 50.00 4 30.0 5.0 C • 0.02-0.06

EC-A4 060-13C06-50 6.00 6.00 13.00 50.00 4 30.0 5.0 C • 0.03-0.07

EC-A4 065-16C08-63 6.50 8.00 16.00 63.00 4 30.0 5.0 C • 0.03-0.07

EC-A4 070-16C08-63 7.00 8.00 16.00 63.00 4 30.0 5.0 C • 0.03-0.08

EC-A4 075-16C08-63 7.50 8.00 16.00 63.00 4 30.0 5.0 C • 0.03-0.08

EC-A4 080-19C08-63 8.00 8.00 19.00 63.00 4 30.0 5.0 C • 0.03-0.09

EC-A4 085-19C10-72 8.50 10.00 19.00 72.00 4 30.0 5.0 C • 0.03-0.09

EC-A4 090-19C10-72 9.00 10.00 19.00 72.00 4 30.0 5.0 C • 0.03-0.09

EC-A4 095-19C10-70 9.50 10.00 19.00 70.00 4 30.0 5.0 C • 0.03-0.09

EC-A4 100-22C10-72 10.00 10.00 22.00 72.00 4 30.0 5.0 C • 0.03-0.10

EC-A4 105-22C12-75 10.50 12.00 22.00 75.00 4 30.0 5.0 C • 0.03-0.10

EC-A4 110-22C12-75 11.00 12.00 22.00 75.00 4 30.0 5.0 C • 0.03-0.10

EC-A4 115-22C12-75 11.50 12.00 22.00 75.00 4 30.0 5.0 C • 0.03-0.10

EC-A4 120-26C12-73 12.00 12.00 26.00 73.00 4 30.0 5.0 C • 0.04-0.11

EC-A4 130-26C12-85 13.00 12.00 26.00 85.00 4 30.0 5.0 C • 0.04-0.11

EC-A4 140-26C12-85 14.00 12.00 26.00 85.00 4 30.0 5.0 C • 0.04-0.12

EC-A4 140-26C14-83 14.00 14.00 26.00 83.00 4 30.0 5.0 C • 0.04-0.12

EC-A4 140-26C16-85 14.00 16.00 26.00 85.00 4 30.0 5.0 C • 0.04-0.12

EC-A4 150-26C16-92 15.00 16.00 26.00 92.00 4 30.0 5.0 C • 0.04-0.12

EC-A4 160-32C16-92 16.00 16.00 32.00 92.00 4 30.0 5.0 C • 0.05-0.13

EC-A4 170-32C16-100 17.00 16.00 32.00 100.00 4 30.0 5.0 C • 0.05-0.13

EC-A4 180-32C18-100 18.00 18.00 32.00 100.00 4 30.0 5.0 C • 0.05-0.13

EC-A4 190-32C20-100 19.00 20.00 32.00 100.00 4 30.0 5.0 C • 0.05-0.13

EC-A4 200-38C20-104 20.00 20.00 38.00 104.00 4 30.0 5.0 C • 0.05-0.13

EC-A4 220-38C20-105 22.00 20.00 38.00 105.00 4 30.0 5.0 C • 0.05-0.13

EC-A4 250-45C25-120 25.00 25.00 45.00 120.00 4 30.0 5.0 C • 0.05-0.13

• The DC tolerance is: 0 - -0.03 mm • For user guide, see pages 177-184

(1) Number of flutes

(2) Maximum ramping angle

(3) C-Cylindrical

Rd°

EC-B4-R DN

4 Flute, 45° Helix Extra-Long Solid DC DCONMS

Carbide Endmills with Various FHA

Corner Radii for Hardened Steel

RE APMX

LH

OAL

HARD MATERIALS

Recommended

Dimensions

Machining Data

IC903 fz

Designation DC DCONMS RE APMX LH DN OAL NOF (1) FHA RMPX° (2) Shank (3) (mm/t)

EC-B4 10-15C08R.5M130 10.00 8.00 0.50 15.00 19.2 7.50 130.00 4 45.0 5.0 C • 0.03-0.10

EC-B4 12-18C10R.5M150 12.00 10.00 0.50 18.00 22.2 9.50 150.00 4 45.0 5.0 C • 0.04-0.11

EC-B4 14-21C12R.5M160 14.00 12.00 0.50 21.00 25.2 11.50 160.00 4 45.0 5.0 C • 0.04-0.12

EC-B4 14-21C12R1M160 14.00 12.00 1.00 21.00 25.2 11.50 160.00 4 45.0 5.0 C • 0.04-0.12

EC-B4 18-27C16R0.5M180 18.00 16.00 0.50 27.00 31.2 15.50 180.00 4 45.0 5.0 C • 0.05-0.13

EC-B4 22-33C20R.5M200 22.00 20.00 0.50 33.00 37.2 19.50 200.00 4 45.0 5.0 C • 0.05-0.13

• For user guide, see pages 177-184

(1) Number of flutes

(2) Maximum ramping angle

(3) C-Cylindrical

150 ISCAR