Page 367 - ISCAR(MILLINGCATALOG 38_2021)

P. 367

CW

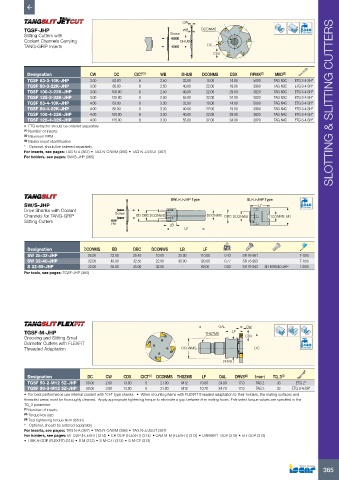

TGSF-JHP WB DCONMS

Slitting Cutters with Screw Bar Max

Coolant Channels Carrying DHUB

TANG-GRIP Inserts DC

CDX

Designation CW DC CICT (1) WB DHUB DCONMS CDX RPMX (2) MIID (3)

TGSF 63-3-10K-JHP 3.00 63.00 6 2.50 32.00 10.00 14.00 5000 TAG N3C ETG 3-4-SH*

TGSF 80-3-22K-JHP 3.00 80.00 6 2.50 40.00 22.00 19.00 3900 TAG N3C ETG 3-4-SH*

TGSF 100-3-22K-JHP 3.00 100.00 6 2.50 40.00 22.00 29.00 3820 TAG N3C ETG 3-4-SH*

TGSF 125-3-32K-JHP 3.00 125.00 8 2.50 55.00 32.00 34.00 3820 TAG N3C ETG 3-4-SH*

TGSF 63-4-10K-JHP 4.00 63.00 6 3.30 32.00 10.00 14.00 5000 TAG N4C ETG 3-4-SH* SLOTTING & SLITTING CUTTERS

TGSF 80-4-22K-JHP 4.00 80.00 6 3.30 40.00 22.00 19.00 3900 TAG N4C ETG 3-4-SH*

TGSF 100-4-22K-JHP 4.00 100.00 6 3.30 40.00 22.00 29.00 3820 TAG N4C ETG 3-4-SH*

TGSF 125-4-32K-JHP 4.00 125.00 8 3.30 55.00 32.00 34.00 3820 TAG N4C ETG 3-4-SH*

• ETG extractor should be ordered separately

(1) Number of inserts

(2) Maximum RPM

(3) Master insert identification

* Optional, should be ordered separately

For inserts, see pages: TAG N-A (367) • TAG N-C/W/M (366) • TAG N-J/JS/JT (367)

For holders, see pages: SW/S-JHP (365)

SW--JHP Type S--JHP Type

SW/S-JHP LF

Drive Shanks with Coolant Screw Bar Max

Channels for TANG-GRIP BD DBC DCONWS DCONMS DBC DCONWS DCONMS BD

Slitting Cutters Pin

LB

LF

Designation DCONMS BD DBC DCONWS LB LF kg

SW 25-32-JHP 25.00 32.00 25.40 10.00 25.00 110.00 0.43 SR 76-961 T-15/5

SW 32-40-JHP 32.00 40.00 32.50 22.00 30.00 120.00 0.77 SR 76-963 T-15/5

S 32-55-JHP 32.00 55.00 45.00 32.00 - 60.00 0.83 SR 76-943 SR M16X40-JHP T-20/5

For tools, see pages: TGSF-JHP (365)

OAL CW

TGSF-M-JHP THSZMS LF

Grooving and Slitting Small CDX

Diameter Cutters with FLEXFIT

Threaded Adaptation DCONMS DC Bar Max

DRVS

Designation DC CW CDX CICT (1) DCONMS THSZMS LF OAL DRVS (2) Insert TQ_3 (3)

TGSF 50-2-M12 5Z-JHP 50.00 2.00 13.00 5 21.00 M12 10.80 24.00 17.0 TAG 2 33 ETG 2*

TGSF 50-3-M12 5Z-JHP 50.00 3.00 13.00 5 21.00 M12 10.70 24.70 17.0 TAG 3 33 ETG 3-4-SH*

• For best performance use internal coolant with "CH" type shanks • When mounting items with FLEXFIT threaded adaptation to their holders, the mating surfaces and

threaded areas must be thoroughly cleaned. Apply appropriate tightening torque to eliminate a gap between the mating faces. Estimated torque values are specified in the

TQ_3 parameter

(1) Number of inserts

(2) Torque key size

(3) Tool tightening torque Nxm (lbfxin)

* Optional, should be ordered separately

For inserts, see pages: TAG N-A (367) • TAG N-C/W/M (366) • TAG N-J/JS/JT (367)

For holders, see pages: BT-ODP (FLEXFIT) (314) • C#-ODP (FLEXFIT) (314) • CAB M-M (FLEXFIT) (312) • DIN69871-ODP (315) • ER-ODP (315)

• HSK A-ODP (FLEXFIT) (316) • S M (312) • S M-C-H (312) • S M-CF (313)

365