Page 368 - ISCAR(MILLINGCATALOG 38_2021)

P. 368

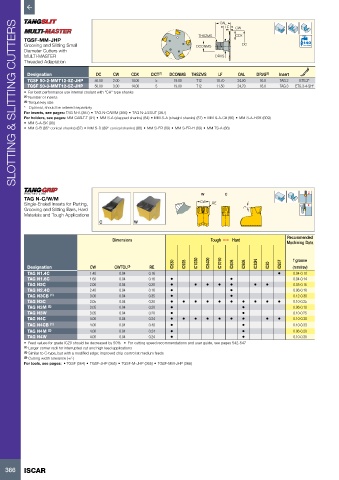

SLOTTING & SLITTING CUTTERS

OAL

LF CW

THSZMS CDX

TGSF-MM-JHP

Grooving and Slitting Small DCONMS DC Bar Max

Diameter Cutters with

MULTI-MASTER DRVS

Threaded Adaptation

Designation DC CW CDX CICT (1) DCONMS THSZMS LF OAL DRVS (2) Insert

TGSF 50-2-MMT12-5Z-JHP 50.00 2.00 14.00 5 19.00 T12 10.70 24.00 16.0 TAG 2 ETG 2*

TGSF 50-3-MMT12-5Z-JHP 50.00 3.00 14.00 5 19.00 T12 11.50 24.70 16.0 TAG 3 ETG 3-4-SH*

• For best performance use internal coolant with "CH" type shanks

(1) Number of inserts

(2) Torque key size

* Optional, should be ordered separately

For inserts, see pages: TAG N-A (367) • TAG N-C/W/M (366) • TAG N-J/JS/JT (367)

For holders, see pages: MM CAB-T-T (91) • MM S-A (stepped shanks) (84) • MM S-A (straight shanks) (87) • MM S-A-C# (86) • MM S-A-HSK (609)

• MM S-A-SK (90)

• MM S-B (85° conical shanks) (87) • MM S-D (89° conical shanks) (88) • MM S-ER (89) • MM S-ER-H (89) • MM TS-A (86)

W C

TAG N-C/W/M

Single-Ended Inserts for Parting, CW RE

Grooving and Slitting Bars, Hard 7º

Materials and Tough Applications

Recommended

Dimensions Tough 1 Hard Machining Data

IC830 IC928 IC1030 IC5400 IC1010 IC808 IC908 IC30N IC20 IC807 f groove

Designation CW CWTOL (3) RE (mm/rev)

TAG N1.4C 1.40 0.04 0.16 • 0.04-0.10

TAG N1.6C 1.60 0.04 0.16 • • 0.04-0.14

TAG N2C 2.00 0.04 0.20 • • • • • • • 0.05-0.16

TAG N2.4C 2.40 0.04 0.16 • • 0.06-0.18

TAG N3CB (1) 3.00 0.04 0.35 • • 0.12-0.30

TAG N3C 3.05 0.04 0.20 • • • • • • • • • • 0.10-0.25

TAG N3M (2) 3.05 0.04 0.20 • • 0.06-0.18

TAG N3W 3.05 0.04 0.20 • • 0.10-0.25

TAG N4C 4.00 0.04 0.24 • • • • • • • • • 0.10-0.30

TAG N4CB (1) 4.00 0.04 0.40 • • 0.10-0.33

TAG N4M (2) 4.00 0.04 0.24 • • 0.06-0.20

TAG N4W 4.00 0.04 0.24 • • 0.10-0.30

• Feed values for grade IC20 should be decreased by 50% • For cutting speed recommendations and user guide, see pages 542-547

(1) Larger corner radii for interrupted cut and high feed applications

(2) Similar to C-type, but with a modified edge; improved chip control at medium feeds

(3) Cutting width tolerance (+/-)

For tools, see pages: • TGSF (364) • TGSF-JHP (365) • TGSF-M-JHP (365) • TGSF-MM-JHP (366)

366 ISCAR