Page 369 - ISCAR(MILLINGCATALOG 38_2021)

P. 369

JT J

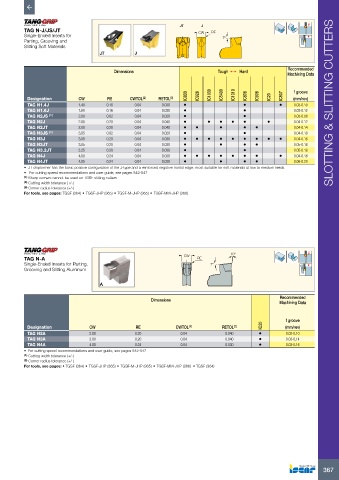

TAG N-J/JS/JT CW RE

Single-Ended Inserts for 7º

Parting, Grooving and

Slitting Soft Materials

Dimensions Tough 1 Hard Recommended

Machining Data

IC830 IC928 IC1030 IC5400 IC1010 IC808 IC908 IC807 f groove

Designation CW RE CWTOL (2) RETOL (3) IC20 (mm/rev)

TAG N1.4J 1.40 0.16 0.04 0.030 • • • 0.03-0.10 SLOTTING & SLITTING CUTTERS

TAG N1.6J 1.60 0.16 0.04 0.030 • • 0.03-0.12

TAG N2JS (1) 2.00 0.02 0.04 0.020 • • 0.03-0.08

TAG N2J 2.00 0.20 0.04 0.040 • • • • • • 0.04-0.12

TAG N2JT 2.00 0.20 0.04 0.040 • • • • • 0.04-0.14

TAG N3JS (1) 3.05 0.02 0.04 0.020 • • 0.04-0.10

TAG N3J 3.05 0.20 0.04 0.030 • • • • • • • • • 0.04-0.16

TAG N3JT 3.05 0.20 0.04 0.030 • • • • 0.05-0.18

TAG N3.2JT 3.25 0.20 0.04 0.030 • • 0.05-0.18

TAG N4J 4.00 0.24 0.04 0.030 • • • • • • • • 0.04-0.18

TAG N4JT 4.05 0.24 0.04 0.030 • • • • 0.06-0.20

• JT chipformer has the basic positive configuration of the J-type and a reinforced negative frontal edge; most suitable for soft materials at low to medium feeds.

• For cutting speed recommendations and user guide, see pages 542-547

(1) Sharp corners cannot be used on TGSF slitting cutters

(2) Cutting width tolerance (+/-)

(3) Corner radius tolerance (+/-)

For tools, see pages: TGSF (364) • TGSF-JHP (365) • TGSF-M-JHP (365) • TGSF-MM-JHP (366)

10°

CW

TAG N-A RE

Single-Ended Inserts for Parting, 7°

Grooving and Slitting Aluminum

Recommended

Dimensions

Machining Data

f groove

Designation CW RE CWTOL (1) RETOL (2) IC20 (mm/rev)

TAG N2A 2.00 0.20 0.04 0.040 • 0.02-0.10

TAG N3A 3.00 0.20 0.04 0.040 • 0.03-0.14

TAG N4A 4.00 0.24 0.04 0.030 • 0.03-0.16

• For cutting speed recommendations and user guide, see pages 542-547

(1) Cutting width tolerance (+/-)

(2) Corner radius tolerance (+/-)

For tools, see pages: • TGSF (364) • TGSF-JHP (365) • TGSF-M-JHP (365) • TGSF-MM-JHP (366) • TGSF (364)

367