Page 457 - ISCAR(MILLINGCATALOG 38_2021)

P. 457

W1

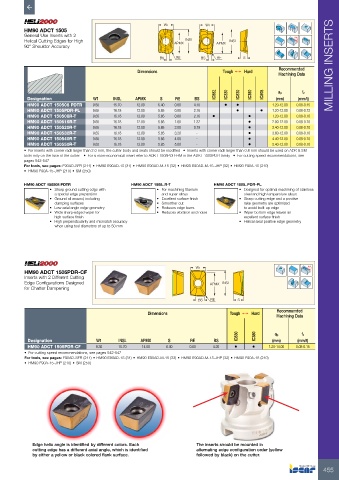

HM90 ADCT 1505 W1

General Use Inserts with 2 Rd°

Helical Cutting Edges for High APMX INSL APMX INSL

90° Shoulder Accuracy

BS RE BS RE S

Dimensions Tough 1 Hard Recommended MILLING INSERTS

Machining Data

IC882 IC330 IC830 IC380 IC808 ap fz

Designation W1 INSL APMX S RE BS (mm) (mm/t)

HM90 ADCT 150508 PDTR 9.50 15.70 12.00 6.40 0.80 4.10 • • 1.20-12.00 0.08-0.15

HM90 ADCT 1505PDR-PL 9.65 16.18 12.00 5.85 0.80 2.16 • • 1.20-12.00 0.08-0.12

HM90 ADCT 150508R-T 9.65 16.18 12.00 5.85 0.80 2.16 • • 1.20-12.00 0.08-0.10

HM90 ADCT 150516R-T 9.65 16.18 12.00 5.85 1.60 1.37 • 2.00-12.00 0.08-0.10

HM90 ADCT 150520R-T 9.65 16.18 12.00 5.85 2.00 0.79 • 2.40-12.00 0.08-0.10

HM90 ADCT 150532R-T 9.65 16.18 12.00 5.85 3.20 - • 3.60-12.00 0.08-0.10

HM90 ADCT 150540R-T 9.65 16.18 12.00 5.85 4.00 - • 4.40-12.00 0.08-0.10

HM90 ADCT 150550R-T 9.65 16.18 12.00 5.85 5.00 - • 5.40-12.00 0.08-0.10

• For inserts with corner radii larger than 2.0 mm, the cutter body and seats should be modified • Inserts with corner radii larger than 0.8 mm should be used on ADK & SM

tools only on the face of the cutter. • For a more economical insert refer to ADKT 1505PDR-HM in the ADKT 1505PDR family • For cutting speed recommendations, see

pages 542-547

For tools, see pages: F90AD-SFR (211) • HM90 E90AD-15 (31) • HM90 E90AD-M-15 (32) • HM90 E90AD-M-15-JHP (32) • HM90 F90A-15 (210)

• HM90 F90A-15-JHP (210) • SM (250)

HM90 ADCT 150508 PDTR HM90 ADCT 1505..R-T HM90 ADCT 1505..PDR-PL

• Sharp ground cutting edge with • For machining titanium • Designed for optimal machining of stainless

a special edge preparation and super alloys steel and high temperature alloys

• Ground all around, including • Excellent surface finish • Sharp cutting edge and a positive

clamping surfaces • Smoother cut rake geometry are optimized

• Low axial angle edge geometry • Reduces edge burrs to avoid built-up edge

• Wide sharp-edged wiper for • Reduces vibration and noise • Wiper bottom edge leaves an

high surface finish excellent surface finish

• High perpendicularity and mismatch accuracy • Helical axial positive edge geometry

when using tool diameters of up to 50 mm

Rd°

HM90 ADCT 1505PDR-CF W1

Inserts with 2 Different Cutting

Edge Configurations Designed APMX lNSL

for Chatter Dampening

BS RE S

Recommended

Dimensions Tough 1 Hard

Machining Data

IC830 IC380 ap fz

Designation W1 INSL APMX S RE BS (mm) (mm/t)

HM90 ADCT 1505PDR-CF 9.30 15.70 14.00 6.40 0.80 4.20 • • 1.20-14.00 0.08-0.15

• For cutting speed recommendations, see pages 542-547

For tools, see pages: F90AD-SFR (211) • HM90 E90AD-15 (31) • HM90 E90AD-M-15 (32) • HM90 E90AD-M-15-JHP (32) • HM90 F90A-15 (210)

• HM90 F90A-15-JHP (210) • SM (250)

Edge helix angle is identified by different colors. Each The inserts should be mounted in

cutting edge has a different axial angle, which is identified alternating edge configuration order (yellow

by either a yellow or black colored flank surface. followed by black) on the cutter.

455