Page 451 - ISCAR(TURNING-CATALOG-42-2022)

P. 451

LH OAL

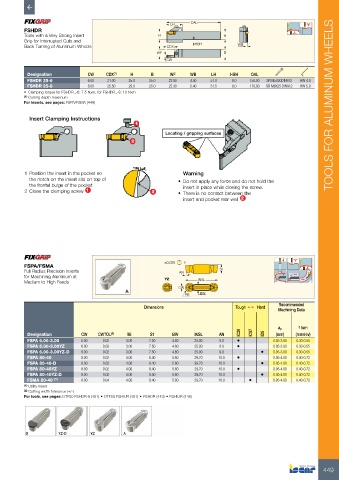

FSHDR

Tools with a Very Strong Insert H H

Grip for Interrupted Cuts and

Back Turning of Aluminum Wheels CDX HBH WB

WF B

CW

Designation CW CDX (1) H B WF WB LH HBH OAL

FSHDR 25-6 6.00 21.00 25.0 25.0 22.80 4.40 51.0 8.0 150.00 SR M5X20DIN912 HW 4.0

FSHDR 25-8 8.00 25.50 25.0 25.0 22.30 5.40 51.5 8.0 170.00 SR M6X25 DIN912 HW 5.0

• Clamping torque for FSHDR..-6: 7.5 Nxm, for FSHDR..-8: 10 Nxm

(1) Cutting depth maximum

For inserts, see pages: FSPA/FSMA (449) TOOLS FOR ALUMINUM WHEELS

Insert Clamping Instructions

Locating / gripping surfaces

1 Position the insert in the pocket so Warning

the notch on the insert sits on top of • Do not apply any force and do not hold the

the frontal bulge of the pocket insert in place while closing the screw.

2 Close the clamping screw 1 • There is no contact between the

insert and pocket rear wall 2

FSPA/FSMA ±0.025

Full Radius Precision Inserts AN S1

for Machining Aluminum at YZ

Medium to High Feeds lNSL

CW

RE BW

Recommended

Dimensions Tough 1 Hard

Machining Data

ap f turn

Designation CW CWTOL (2) RE S1 BW INSL AN IC20 IC07 ID5 (mm) (mm/rev)

FSPA 6.00-3.00 6.00 0.02 3.00 7.50 4.60 25.00 9.0 • 0.05-3.00 0.30-0.55

FSPA 6.00-3.00YZ 6.00 0.02 3.00 7.50 4.60 25.00 9.0 • 0.05-3.00 0.30-0.55

FSPA 6.00-3.00YZ-D 6.00 0.02 3.00 7.50 4.60 25.00 9.0 • 0.05-3.00 0.30-0.55

FSPA 80-40 8.00 0.02 4.00 8.40 5.60 29.70 10.0 • 0.05-4.00 0.40-0.72

FSPA 80-40-D 8.00 0.02 4.00 8.40 5.60 29.70 10.0 • 0.05-4.00 0.40-0.72

FSPA 80-40YZ 8.00 0.02 4.00 8.40 5.60 29.70 10.0 • 0.05-4.00 0.40-0.72

FSPA 80-40YZ-D 8.00 0.02 4.00 8.40 5.60 29.70 10.0 • 0.05-4.00 0.40-0.72

FSMA 80-40 (1) 8.00 0.04 4.00 8.40 5.60 29.70 10.0 • 0.05-4.00 0.40-0.72

(1) Utility insert

(2) Cutting width tolerance (+/-)

For tools, see pages: DTF50 FSHDR-8 (451) • DTF50 FSHIUR (451) • FSHDR (449) • FSHIUR (448)

449