Page 523 - ISCAR(TURNING-CATALOG-42-2022)

P. 523

CUTDIA

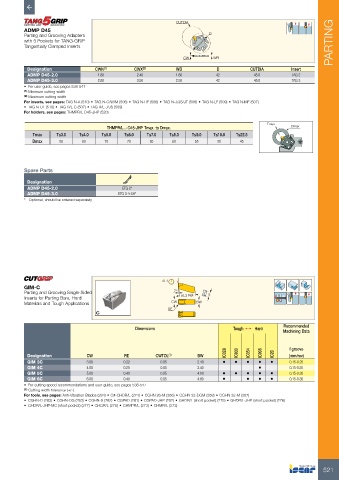

ADMP D45

Parting and Grooving Adapters D

with 5 Pockets for TANG-GRIP PARTING

Tangentially Clamped Inserts

CW WB

Designation CWN (1) CWX (2) WB D CUTDIA Insert

ADMP D45-2.0 1.80 2.40 1.60 42 45.0 TAG 2

ADMP D45-3.0 2.80 3.50 2.50 42 45.0 TAG 3

• For user guide, see pages 538-547

(1) Minimum cutting width

(2) Maximum cutting width

For inserts, see pages: TAG N-A (510) • TAG N-C/W/M (506) • TAG N-HF (506) • TAG N-J/JS/JT (508) • TAG N-LF (509) • TAG N-MF (507)

• TAG N-UT (510) • TAG R/L-C (507) • TAG R/L-J/JS (509)

For holders, see pages: THMPR/L D45-JHP (520)

Tmax

THMPR/L...-D45-JHP Tmax. to Dmax. Dmax

Tmax T≤3.0 T≤4.0 T≤5.0 T≤6.0 T≤7.0 T≤8.0 T≤9.0 T≤10.0 T≤22.5

Dmax 85 80 75 70 65 60 55 50 45

Spare Parts

Designation

ADMP D45-2.0 ETG 2*

ADMP D45-3.0 ETG 3-4-SH*

* Optional, should be ordered separately

±0.1

GIM-C

Parting and Grooving Single-Sided 7° 5

Inserts for Parting Bars, Hard 15.3 Ref.

Materials and Tough Applications CW BW

RE

Recommended

Dimensions Tough 1 Hard

Machining Data

Designation CW RE CWTOL (1) BW IC328 IC830 IC354 IC908 IC20 f groove

(mm/rev)

GIM 3C 3.00 0.22 0.05 2.40 • • • • • 0.15-0.25

GIM 4C 4.00 0.25 0.05 3.40 • 0.15-0.25

GIM 5C 5.00 0.40 0.05 4.00 • • • • • 0.15-0.30

GIM 6C 6.00 0.40 0.05 4.80 • • • • 0.15-0.30

• For cutting speed recommendations and user guide, see pages 538-547

(1) Cutting width tolerance (+/-)

For tools, see pages: Anti-Vibration Blades (284) • C#-GHDR/L (274) • CGHN 26-M (356) • CGHN 32-DGM (358) • CGHN 32-M (357)

• CGHN-D (283) • CGHN-DG (283) • CGHN-S (282) • CGPAD (281) • CGPAD-JHP (282) • GHDR/L (short pocket) (275) • GHDR/L-JHP (short pocket) (276)

• GHDR/L-JHP-MC (short pocket) (277) • GHGR/L (278) • GHMPR/L (273) • GHMR/L (273)

521