Page 526 - ISCAR(TURNING-CATALOG-42-2022)

P. 526

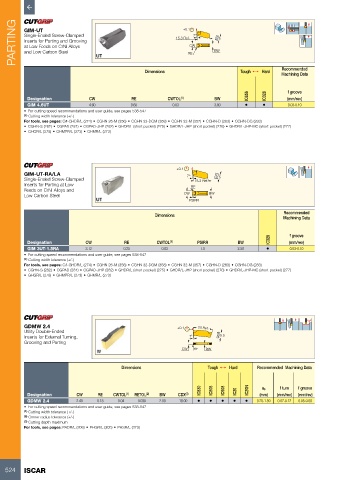

PARTING GIM-UT 15.3 Ref. RE 7° BW 5

±0.1

Single-Ended Screw-Clamped

Inserts for Parting and Grooving

at Low Feeds on CrNi Alloys

CW

and Low Carbon Steel

Dimensions Tough 1 Hard Recommended

Machining Data

Designation CW RE CWTOL (1) BW IC656 IC328 f groove

(mm/rev)

GIM 4.6UT 4.60 0.60 0.03 3.80 • • 0.03-0.10

• For cutting speed recommendations and user guide, see pages 538-547

(1) Cutting width tolerance (+/-)

For tools, see pages: C#-GHDR/L (274) • CGHN 26-M (356) • CGHN 32-DGM (358) • CGHN 32-M (357) • CGHN-D (283) • CGHN-DG (283)

• CGHN-S (282) • CGPAD (281) • CGPAD-JHP (282) • GHDR/L (short pocket) (275) • GHDR/L-JHP (short pocket) (276) • GHDR/L-JHP-MC (short pocket) (277)

• GHGR/L (278) • GHMPR/L (273) • GHMR/L (273)

±0.1

GIM-UT-RA/LA 7°

Single-Ended Screw-Clamped 15.3 Ref. 5

Inserts for Parting at Low RE

Feeds on CrNi Alloys and

Low Carbon Steel CW BW

PSIRR

Dimensions Recommended

Machining Data

IC328 f groove

Designation CW RE CWTOL (1) PSIRR BW (mm/rev)

GIM 3UT-1.5RA 3.12 0.25 0.03 1.5 2.50 • 0.03-0.10

• For cutting speed recommendations and user guide, see pages 538-547

(1) Cutting width tolerance (+/-)

For tools, see pages: C#-GHDR/L (274) • CGHN 26-M (356) • CGHN 32-DGM (358) • CGHN 32-M (357) • CGHN-D (283) • CGHN-DG (283)

• CGHN-S (282) • CGPAD (281) • CGPAD-JHP (282) • GHDR/L (short pocket) (275) • GHDR/L-JHP (short pocket) (276) • GHDR/L-JHP-MC (short pocket) (277)

• GHGR/L (278) • GHMPR/L (273) • GHMR/L (273)

GDMW 2.4 ±0.1 20 Ref.

Utility Double-Ended

Inserts for External Turning, 7˚ 5.5

Grooving and Parting

CW RE BW

Dimensions Tough 1 Hard Recommended Machining Data

IC830 IC808 IC908 IC20 IC20N ap f turn f groove

Designation CW RE CWTOL (1) RETOL (2) BW CDX (3) (mm) (mm/rev) (mm/rev)

GDMW 2.4 2.40 0.18 0.04 0.030 2.00 18.00 • • • • • 0.25-1.50 0.07-0.12 0.05-0.08

• For cutting speed recommendations and user guide, see pages 538-547

(1) Cutting width tolerance (+/-)

(2) Corner radius tolerance (+/-)

(3) Cutting depth maximum

For tools, see pages: PADR/L (306) • PHGR/L (305) • PHSR/L (373)

524 ISCAR